Neoprene Foam

Materials

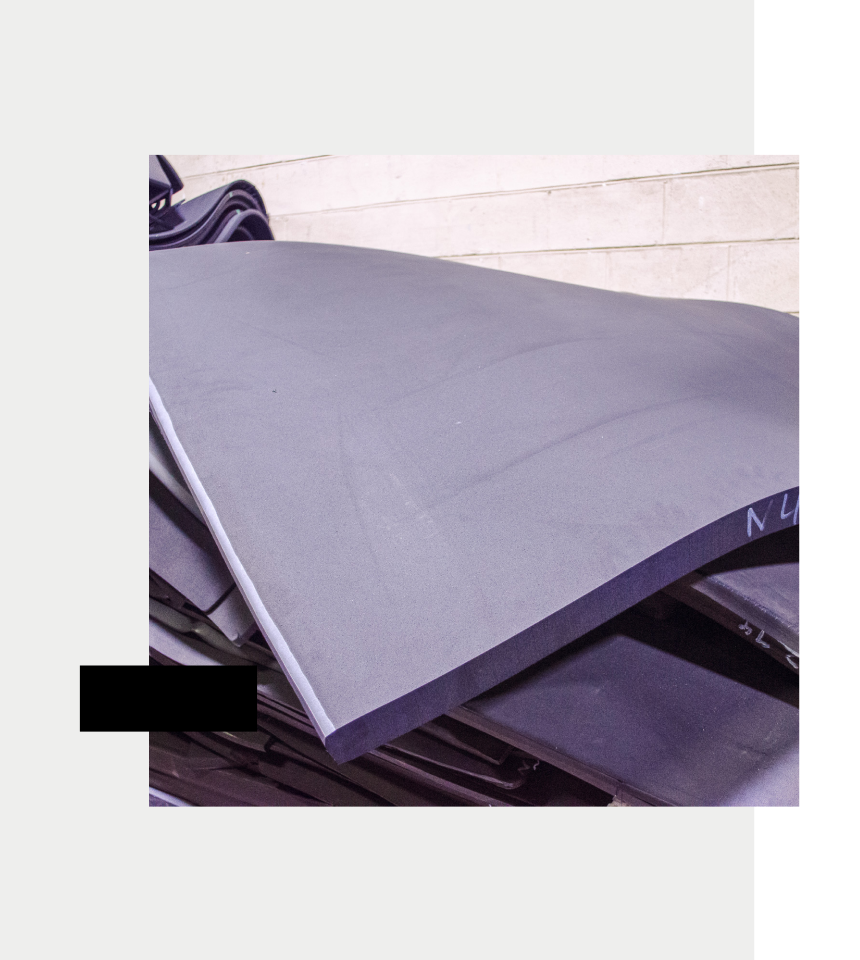

Neoprene Foam

Neoprene foam, also known as polychloroprene foam, is a synthetic rubber product known for its exceptional durability, flexibility, and resistance to various environmental factors. It is widely used in applications requiring strong cushioning and insulation properties, as well as a reliable gasket material for its impermeability.

What is Neoprene Foam?

Neoprene foam is technically a synthetic rubber, but it can be manufactured as either a solid rubber or foam material. The material is considered an elastomer (a natural or synthetic polymer with elastic properties).

Neoprene is made from chloroprene, a monomer that polymerizes to form polychloroprene. The foam is created by introducing gas into the polychloroprene during the polymerization process, resulting in a closed cell structured foam. The foam is then cured and can be cut into various shapes and sizes for different applications.

The Strengths of Neoprene Foam:

- Density: From low to high, affecting firmness and cushioning.

- Flexibility: Highly flexible, maintaining its properties over a wide temperature range. It’s also naturally form–fitting, increasing its ability to properly form an airtight seal.

- Resilience: It has excellent compression set resistance, stress relaxation, and compression recovery. It’s also physically tough, durable, and tear–resistant

- Thermal Insulation: Good insulating properties against heat and cold. It’s also resistant to heat and flames.

- Chemical Resistance: Resistant to oils, solvents, and many chemicals.

- Water Resistance: Excellent resistance to water absorption and buoyancy.

- Weather Durability: It will not degrade due to exposure to sunlight, ozone, and other weather conditions.

- Vibration Dampening: It can be used to reduce NVH (noise, vibration, and harshness).

The Drawbacks of Neoprene Foam

- Cost: The material can be more expensive than other foams.

- Oxidizers: The material is not resistant to oxidizing acids and some other hydrocarbons.

- Electrical Insulation: The materials is not recommended for electrical applications.

Interested in Neoprene Foam?

Get a Sample Sent Right to Your Business.

The Applications of Neoprene Foam

- Marine: Wetsuits, buoyancy aids, and marine insulation due to its excellent water resistance.

- Automotive: Gaskets, seals, and padding for its durability and chemical resistance.

- Sports Equipment: Protective gear, mats, and grips for its cushioning and impact resistance.

- Medical: Orthopedic braces, supports, and padding.

- Construction: Soundproofing and insulation due to its thermal and acoustic properties.

- Electronics: Foam inserts for protecting delicate components.

- Aerospace: Lightweight, durable padding and insulation materials.

- Industrial: Custom gaskets, seals, and cushioning materials.

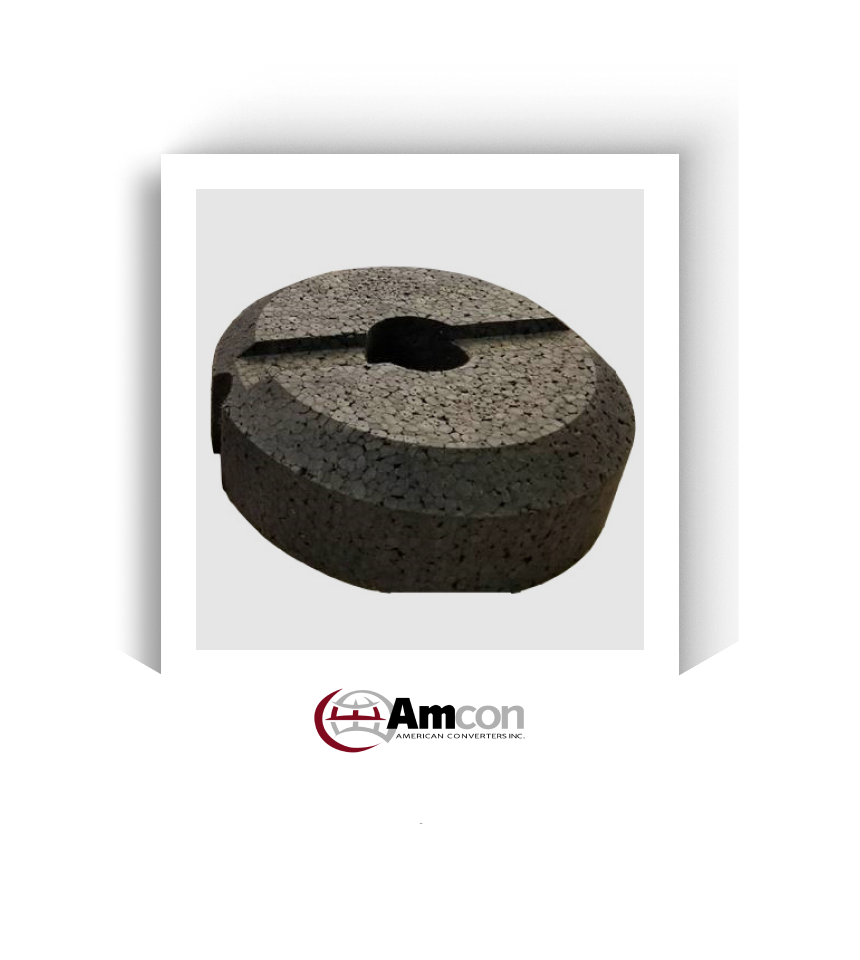

Amcon Fabricates Custom Neoprene Foam

At Amcon foam, we custom fabricate neoprene foam can be fabricated into a variety of shapes and size for multiple industries and applications, creating custom foam parts for:

- Protective Packaging

- Gasketing

- Manufactured Products

Learn More About Our Custom Foam Fabrication Capabilities

Technical Documents for Polyurethane Foam

Packaging Foam Material Specs

“We’ve been sourcing Amcon foam products to use in thousands of our client facilities for more than two decades. Their product quality and customer service are second to none.”

KYLE F.

President, Company Confidential