Polyurethane (PU) Foam

Materials

Polyurethane (PU) Foam

Polyurethane (PU) foam is a versatile and widely used material known for its excellent cushioning, insulation, and structural properties. It’s widely used as a packaging material, insulation material, and as a component in many products from a wide range of industries. It’s also notable for being the primary component of foam mattresses and commercial and residential furniture.

What is Polyurethane Foam?

Polyurethane Foam is a soft, low-density foam (although high density PU foam options are available). The foam is a polymer that is composed of organic units joined by urethane links, resulting from the reaction between polyols and diisocyanates.

The primary components of polyurethane foam include:

- Polyols: polyether or polyester-based compounds that determine the foam’s flexibility and resilience.

- Diisocyanates: typically, TDI (Toluene Diisocyanate) or MDI (Methylene Diphenyl Diisocyanate), which react with polyols to form the urethane bonds.

Polyurethane foam is produced through a process called polymerization, where polyols and diisocyanates are mixed with catalysts, surfactants, and blowing agents. The reaction generates heat and gas, creating a foam that can be molded into various shapes and sizes. The foam is then cured to stabilize its structure. Blowing agents are also used to create the foam’s cellular structure by producing gas during the reaction.

The Strengths of Polyurethane Foam:

- Range of Densities: from very low to high, affecting the foam’s hardness and durability.

- Flexibility: the foam varies from soft and cushioning to rigid and structural.

- Resilience: it can return to its original shape after compression.

- Thermal Insulation: it has excellent insulating properties, making it ideal for temperature control applications.

- Chemical Resistance: it’s resistant to many solvents and chemicals, though susceptibility varies with formulation.

- Versatility: can be formulated to be flexible or rigid, catering to a wide range of applications.

- Comfort: excellent cushioning properties for comfort and protection. It’s also nonabrasive.

- Lightweight: high strength-to-weight ratio.

- Durability: long-lasting with good wear resistance.

The Drawbacks of PU Foam

- Cost: can be more expensive than other foams.

- Sensitivity to UV Light: susceptible to degradation when exposed to sunlight.

- Flammability: requires the addition of flame retardants to meet UL 94 safety standards.

Interested in Polyurethane PU Foam?

Get a Sample Sent Right to Your Business.

Ester Polyurethane Foam vs Ether Polyurethane Foam

Ester and ether urethanes differ based on their bases, with ester PU foam having a polyester base and ether PU having a polyether triol base. These bases, when combined with differing additives, result in two similar types of foam that have different properties:

Ester Polyurethane Foam

- Density: generally higher than ether foams.

- Durability: more resistant to abrasion and wear.

- Chemical Resistance: superior resistance to hydrocarbons, oils, and fuels.

- Hydrolytic Stability: less resistant to moisture and hydrolysis, prone to degradation in humid conditions.

Ether Polyurethane Foam

- Density: typically lower, offering greater flexibility and softness.

- Durability: good tensile strength and resilience.

- Chemical Resistance: excellent resistance to water and most solvents.

- Hydrolytic Stability: superior resistance to moisture, making it more suitable for humid environments.

The Applications of Polyurethane Foam

- Automotive Industry: used in seating, headrests, armrests, and insulation.

- Construction: insulation panels, sealants, and adhesives.

- Furniture: cushions, mattresses, and padding.

- Medical: prosthetics, orthotics, and medical mattresses.

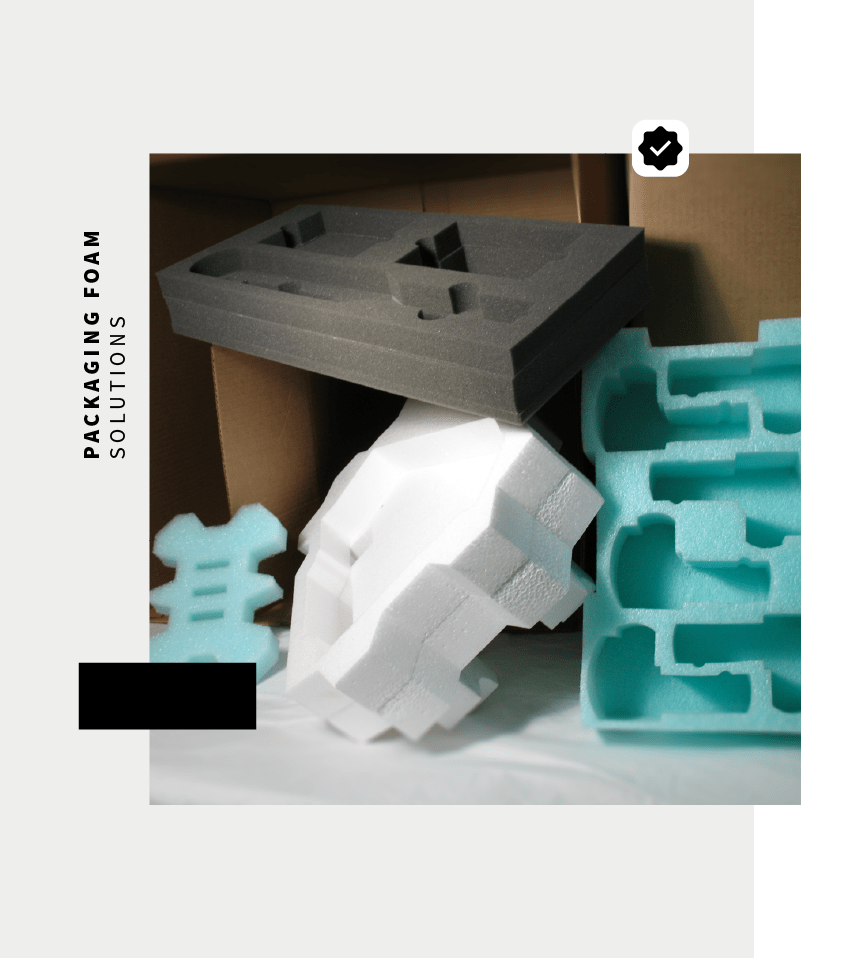

- Packaging: protective packaging for delicate items.

- Electronics: foam inserts for component protection and thermal management.

- Aerospace: lightweight, high-strength components and insulation.

- Appliance Manufacturing: insulating layers in refrigerators and freezers.

- Marine: buoyancy aids and anti-vibration pads.

Amcon Fabricates Custom Polyurethane Foam

At Amcon Foam, we leverage many fabrication techniques to custom cut and shape polyurethane so it can be tailored to meet the exact specifications and requirements of your applications, ensuring optimal performance and cost-efficiency. We fabricate:

- Custom Protective Packaging for Shipping

- Custom Case Inserts

- Custom Foam Parts for Original Equipment Manufacturers (OEMs)

Learn More About Our Custom Foam Fabrication Capabilities

Technical Documents for Polyurethane Foam

Packaging Foam Material Specs

“We’ve been sourcing Amcon foam products to use in thousands of our client facilities for more than two decades. Their product quality and customer service are second to none.”

KYLE F.

President, Company Confidential