Beaded Expanded Polyethylene (EPE)

Materials

Beaded Expanded Polyethylene (EPE)

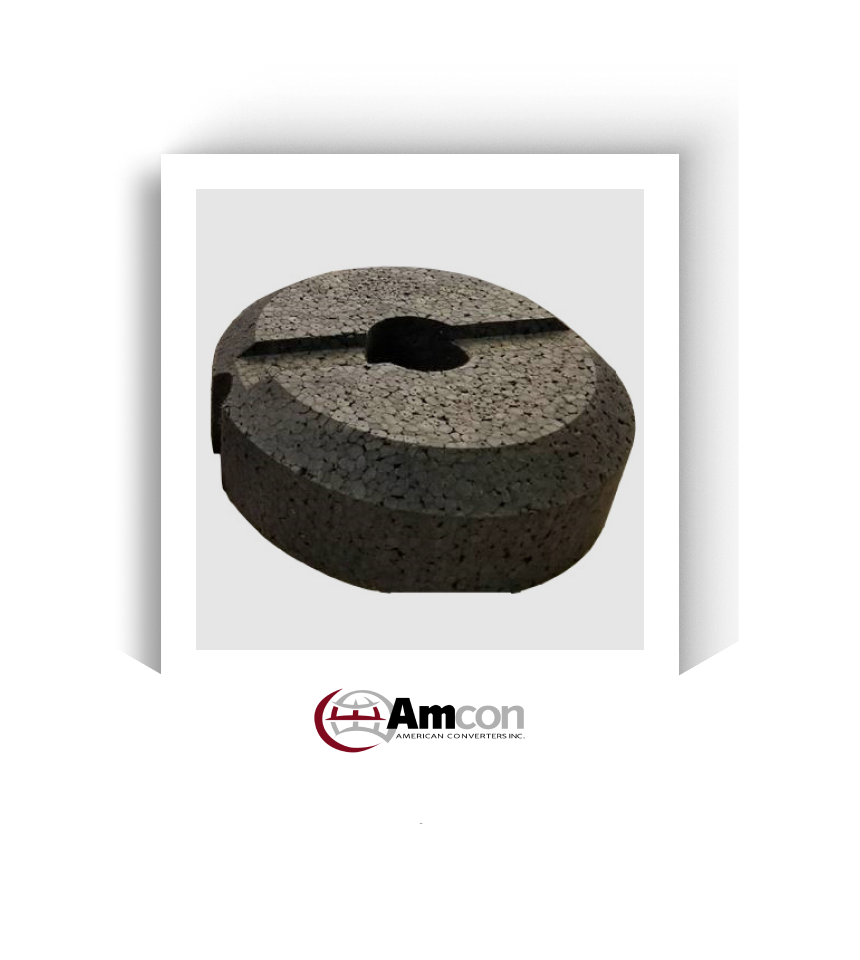

Expanded Polyethylene (EPE) foam is a lightweight beaded foam that is widely used in protective packaging, consumer products, and various industrial applications. It’s typically made from expanded polyethylene pellets, which give it its characteristic beaded appearance.

What is Expanded Polyethylene (EPE) Foam?

EPE foam is made from LLDPE polyethylene resin, a thermoplastic polymer. EPE is produced by expanding polyethylene resin into beads and then block molding into planks using heat and high pressure, resulting in a closed-cell isotropic structure which creates a rigid material that has excellent repetitive cushioning properties and impact resistance in all directions.

The Strengths of Expanded Polyethylene (EPE) Foam:

- Impact Resistance: EPE foam is best for repetitive dynamic cushioning provides excellent shock absorption and impact resistance, to protect fragile products during shipping, long term storage and handling.

- Sustainability: EPE is non-crosslinked and 100% recyclable. EPE can reduce the foam cushions carbon footprint by 40% at the design stage or re-design stage. EPE is re-melted back to the base resin and used time and again.

- Class A: EPE has been used for more than 20 years in Class A automotive dunnage applications. EPE is used to separate and protect high gloss painted parts, chrome, glass, and powder coated components.

- Dimensional Stability: EPE is 3X more dimensionally stable at higher temperatures and will not shrink after fabrication like other closed cell foams making it ideal for tight tolerance, critical fit parts, and case inserts.

- Lightweight: EPE foam is 40% lighter than equivalent products making it ideal for reducing shipping classes, cubing down packages and improved ergonomics.

- Chemical Resistance: EPE is resistant to hundreds of chemicals, including acids and alkalis, which make it the choice for industrial applications.

- Thermal Insulation: EPE foam provides 4R per inch of thermal insulation, making it perfect for durable cold chain applications and refrigerated partitions.

The Drawbacks of Expanded Polyethylene (EPE) Foam:

- UV Sensitivity: Uncovered EPE foam can degrade when exposed to long term ultraviolet (UV) light. Covered or coated EPE parts work well for marine collars, under boat decks, and wall padding.

- Lower Durability vs. High Density XLPE: While EPE foam is flexible and resilient, it may not offer the same level of durability as #6.0 XLPE. However, EPE #1.5 and EPE #2.3 are more durable than #2 and #4 XLPE.

- Aesthetics: EPE is a bead foam and has tiny gaps between some of the beads that can show on the foams cut surface.

Interested in Expanded Polyethylene (EPE) Foam?

Get a Sample Sent Right to Your Business.

The Applications of Expanded Polyethylene (EPE) Foam

- Cushion Packaging: EPE foam is used for both heavy and delicate packaging of high value products, such as electronics, sensors/optics, glass, medical instruments, and crating. EPE meets the most difficult packaging environments and can take hundreds of drops and return to its original shape.

- Automotive: EPE foam is used extensively for high gloss painted automotive parts such as interior and exterior trim components.

- Medical: EPE foam is used for packaging sensitive and expensive medical devices and equipment. EPE foam is physically expanded and will not off-gas.

- Military: EPE is certified to meet CID-A-A-59136, CID-A-A-59135, and PPP-1752D. EPE is recognized by the US Navy with an active material print/drawing on file. EPE is used for containerization of sensitive parts, weight reduction, missile packs, blocking and bracing dunnage for crating, fuses, ordinance, solid 6” plank for less bonding, and case inserts.

Amcon Foam Fabricates Custom EPE Foam Parts

EPE foam can be fabricated into custom packaging and foam parts for original equipment manufacturers (OEMs). At Amcon, we partner with businesses to create custom parts no matter the specifications or application used. Our precise fabrication techniques allow us to maintain tight tolerances on every part we make.

Learn More About Our Custom Foam Fabrication Capabilities

Technical Documents for EPE Foam

Packaging Foam Material Specs

“We’ve been sourcing Amcon foam products to use in thousands of our client facilities for more than two decades. Their product quality and customer service are second to none.”

KYLE F.

President, Company Confidential