Cross-Linked Polyethylene (XLPE) Foam

Materials

Cross-Linked Polyethylene (XLPE) Foam

Cross-linked polyethylene (XLPE) foam is a versatile and resilient closed-cell foam known for its durability, excellent thermal insulation, and water-resistant properties. This material is widely used in various industries due to its superior performance, adaptability, and cushioning properties.

What is Cross-Linked Polyethylene (XLPE) Foam?

Cross-linked polyethylene foam is made from a base of polyethylene, a polymer composed of long chains of ethylene monomers. The “cross-linking” process involves creating chemical bonds between these polymer chains by adding blowing and cross-linking agents. The mixture is heated, causing the blowing agents to create gas bubbles while the cross-linking agents form chemical bonds between polymer chains. This results in the expansion and solidification of the foam with a closed-cell structure, enhancing the foam’s physical properties and making it more robust and stable. XLPE foam can also be cross linked using a process called irradiation – the result is a fully cross-linked foam that is very clean and not prone to the off-gas process you see in chemically cross-linked foams.

The Strengths of XLPE Foam:

- Range of Densities: XLPE foam comes in a range of densities that can be tailored to specific application requirements.

- Thermal Insulation: XLPE’s closed-cell structure provides excellent thermal insulation, making it ideal for temperature-sensitive applications.

- Water Resistance: XLPE’s closed-cell nature also ensures high resistance to water absorption and moisture.

- Chemical Resistance: XLPE foam is resistant to many chemicals, oils, and solvents, allowing it to be used in harsh industrial environments.

- Flexibility and Cushioning: XLPE is highly flexible and offers excellent shock absorption and cushioning.

- Strength to Weight Ratio: XLPE foam is lightweight and strong, making it a great shipping foam.

- Durability: XLPE foam is highly durable and resistant to environmental factors, including UV radiation and moisture.

- Excellent Insulation: XLPE provides high thermal and acoustic insulation due to its closed-cell structure.

- Versatility: XLPE can be easily fabricated into various shapes and sizes to meet specific requirements.

The Weaknesses of XLPE Foam

- Cost: XLPE foam can be more expensive than non-cross-linked polyethylene foams due to the additional processing required.

- Limited High-Temperature Resistance: while it has good thermal properties, XLPE foam may not perform well in extremely high-temperature environments compared to other specialized materials.

Interested in Cross-Linked Polyethylene Foam?

Get a Sample Sent Right to Your Business.

The Applications of XLPE Foam

- Construction: thermal insulation for pipes, ductwork, and building insulation due to its excellent insulating properties. It can also be used as soundproofing.

- Automotive: gaskets, seals, and cushioning components due to its resistance to chemicals and durability.

- Packaging: custom-molded XLPE foam inserts protect delicate and high-value items during shipping, including electronics that need anti-static protection.

- Fitness Mats: XLPE can be used in exercise and yoga mats.

- Medical: orthopedic supports and braces, medical devices, and prosthetics.

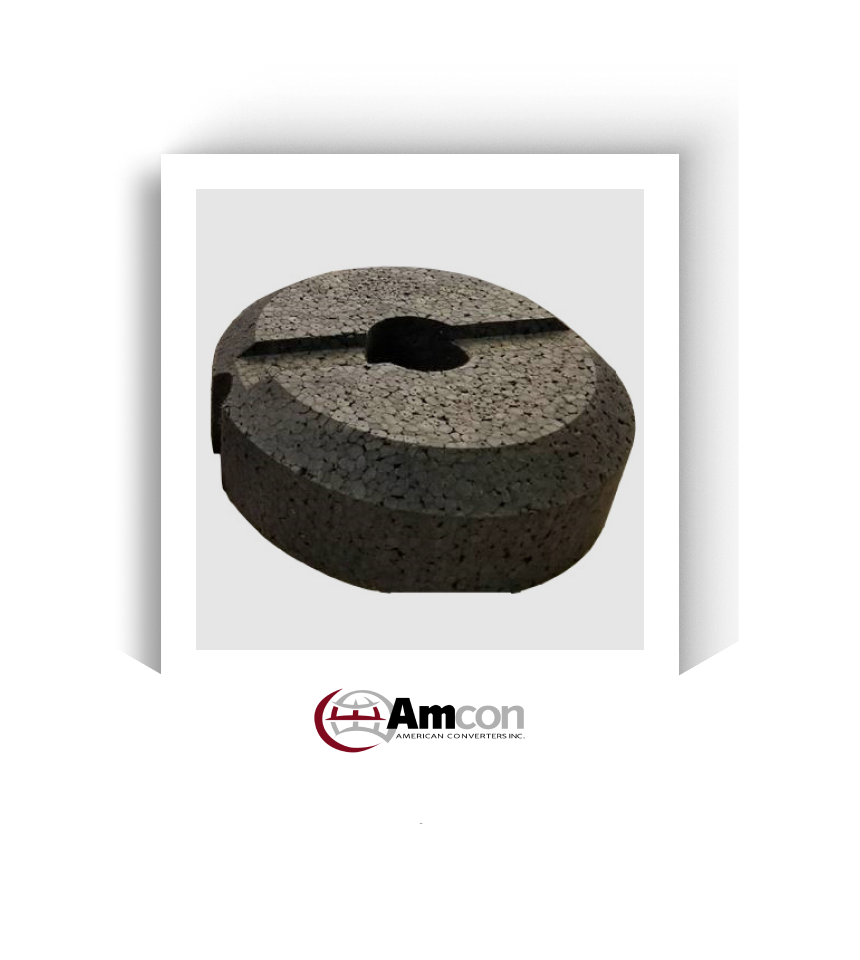

Amcon Fabricates Custom XLPE Foam Products

At Amcon, we custom fabricate XLPE foam products and shipping inserts. XLPE can be customized into many shapes and sizes using die cutting and thermoforming processes. We also offer lamination services, layering multiple sheets of foam to achieve desired thickness and properties for added protection.

Learn More About Our Custom Foam Fabrication Capabilities

Technical Documents for XLPE Foam

Packaging Foam Material Specs

“We’ve been sourcing Amcon foam products to use in thousands of our client facilities for more than two decades. Their product quality and customer service are second to none.”

KYLE F.

President, Company Confidential