Polyethylene (PE) Foam

Materials

Polyethylene (PE) Foam

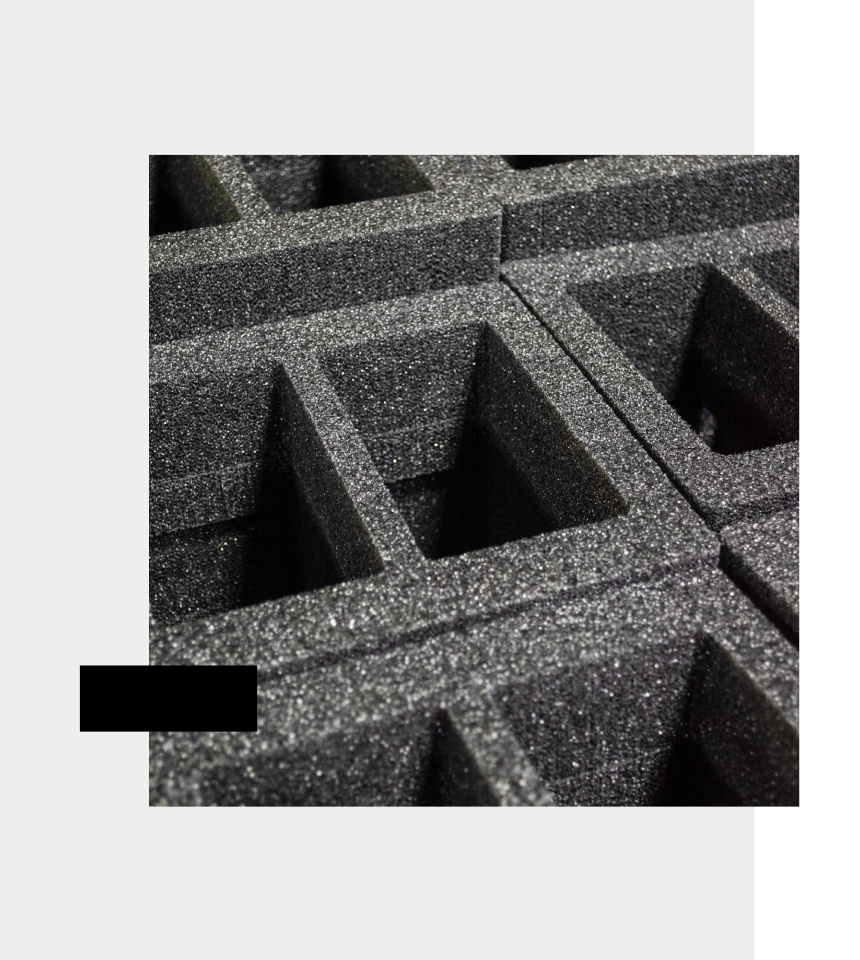

Polyethylene (PE) foam is a durable, lightweight, and versatile material. From packaging to floatation devices, PE foam is commonly used in various applications across multiple industries. It’s a popular plastic-like foam material that also comes in other manufactured varieties, including expanded polyethylene (EPE), beaded polyethylene, and cross-linked polyethylene (XLPE).

What is Polyethylene Foam?

Polyethylene is one of the most produced thermoplastics in the world. It’s a member of the polyolefin resins family used in polyethylene production. Polyethylene foam is produced through a process called extrusion. The polyethylene resin is melted and mixed with a blowing agent, which generates gas bubbles within the resin, creating a foamed structure as it cools and solidifies. This results in a closed cell material that is flexible, resilient, water resistant, and buoyant.

During the manufacturing process, several additives can be applied to change the chemical composition of the polymer and create different types of foams with properties that range from anti-static to fire retardancy.

The Strengths of Polyethylene Foam:

- Range of Densities: from low to high, affecting firmness and cushioning.

- Resilience: it has a high impact resistance and ability to return to original shape after compression. It also has good tear resistance, shock absorption and strength to weight ratio.

- Thermal Insulation: it’s effective in reducing heat transfer.

- Chemical Resistance: it’s resistance to many chemicals, oils, and solvents.

- Moisture Resistance: PE foam resists hydrolysis, meaning it won’t break down in water. It also resists mold and mildew.

- Buoyancy: the material floats easily.

- Non-abrasive: Most formulations of PE foam are not considered to provide Class A surface protection. For many surfaces – PE foam should be relatively non-marring.

The Drawbacks of Polyethylene Foam

- Low Soundproofing: it does not insulate against noise

- UV Resistance: the foam does not last long in areas of high sunlight

- Flexibility: the material loses flexibility if it is manufactured at high thicknesses

Interested in Polyethylene PE Foam?

Get a Sample Sent Right to Your Business.

The Applications of Polyethylene Foam

- Packaging: protective packaging for electronics, appliances, and delicate items.

- Construction: insulation boards, expansion joint fillers, and sealants.

- Automotive: interior padding, gaskets, and sound dampening materials.

- Medical: orthopedic supports, prosthetics, and padding.

- Sports and Leisure: pool noodles, flotation devices, and protective gear.

- Consumer Products: Protective padding and safety devices.

- Electronics: foam inserts for shock absorption and protection.

- Marine: buoyancy aids and flotation components.

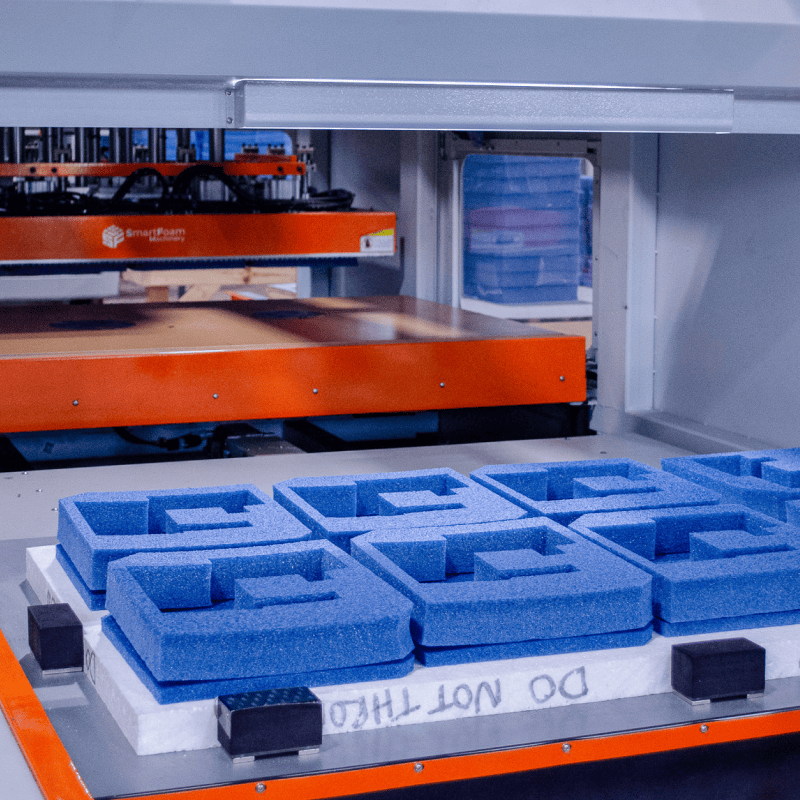

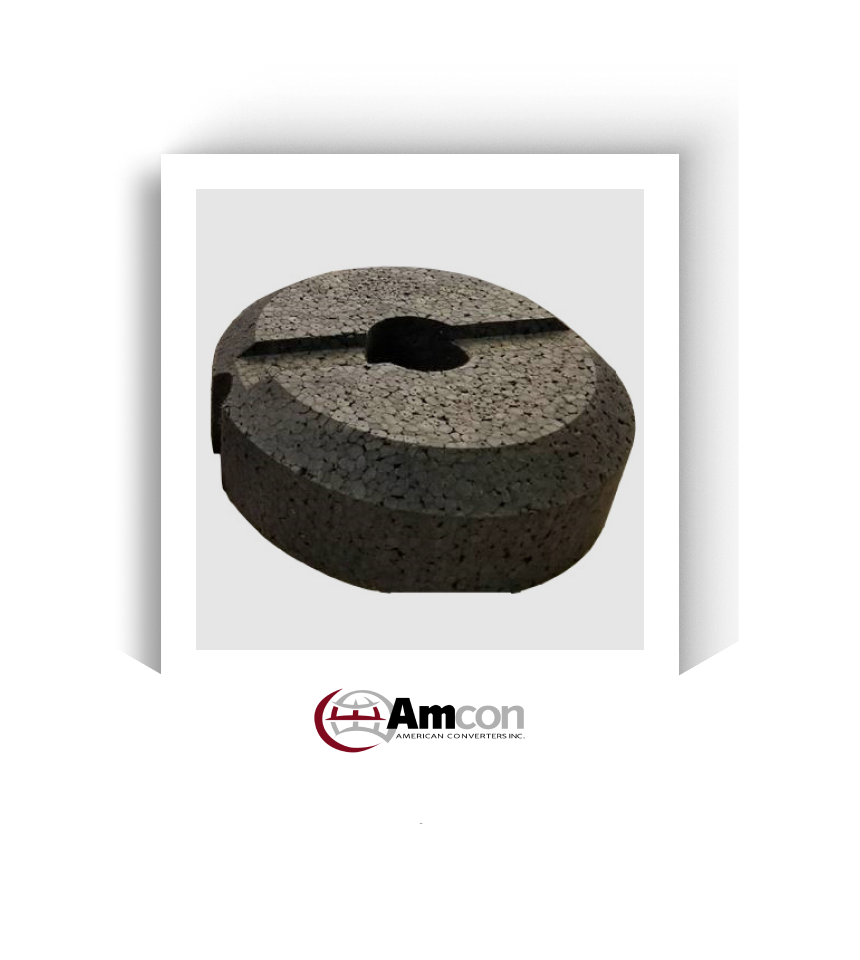

Amcon Fabricates Custom Polyethylene Foam

At Amcon Foam, we fabricate polyethylene foam into custom shapes and sizes for protective packaging and any other application in any industry. From die cutting to lamination and thermoforming, we create custom foam parts for:

- Shippers to Use as Protective Packaging

- Custom Case Inserts

- Custom Foam Parts for Original Equipment Manufacturers (OEMs)

Learn More About Our Custom Foam Fabrication Capabilities

Technical Documents for Polyurethane Foam

Packaging Foam Material Specs

“We’ve been sourcing Amcon foam products to use in thousands of our client facilities for more than two decades. Their product quality and customer service are second to none.”

KYLE F.

President, Company Confidential