Expanded Polypropylene (EPP)

Materials

Expanded Polypropylene (EPP)

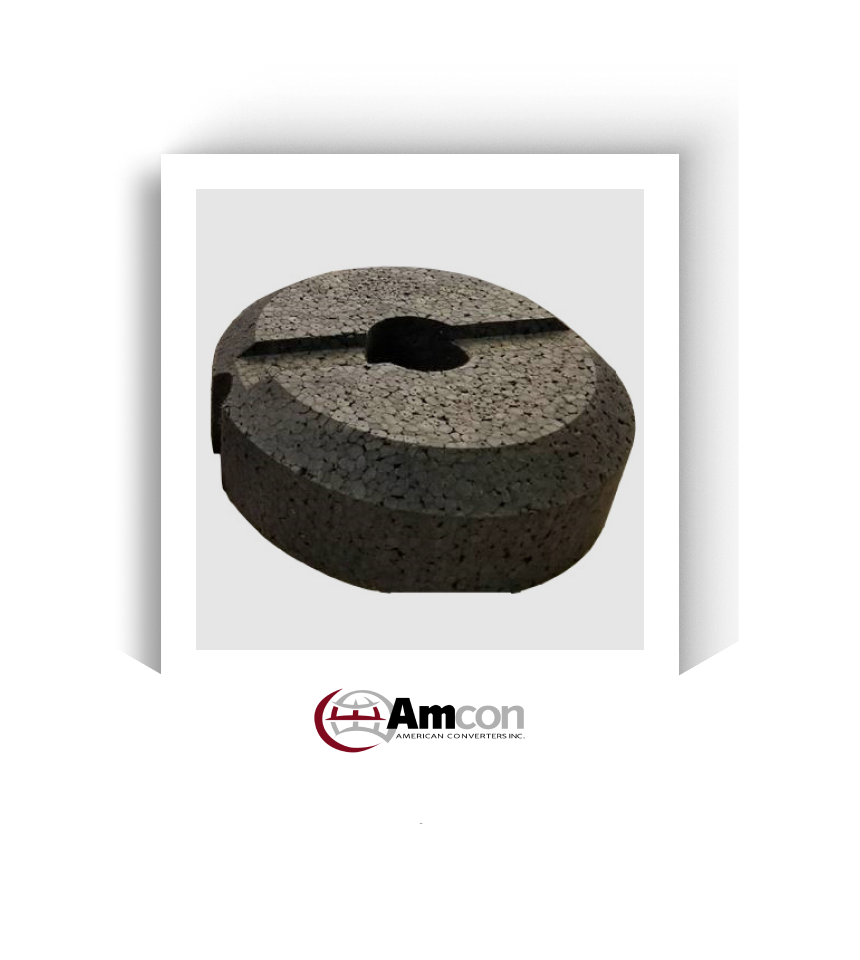

Expanded Polypropylene (EPP) foam is a highly versatile and durable material extensively used in various industrial and commercial applications. Being a closed cell beaded foam, it is most known for its ability to absorb energy, manage temperature, and withstand heavy loads and impacts.

What is Expanded Polypropylene (EPP) Foam?

EPP foam is made from polypropylene, a type of thermoplastic polymer known for its excellent mechanical properties and chemical resistance. As a beaded foam, EPP is produced by expanding polypropylene beads and then molding them into planks under heat and pressure, creating a lightweight, resilient material with a closed-cell structure.

Strengths of Expanded Polypropylene Foam:

- Lightweight: EPP foam is incredibly lightweight, making it ideal for applications where weight reduction is crucial, such as in automotive and aerospace industries. This also helps with creating lightweight packaging.

- Durability: EPP foam is highly durable and can withstand repeated impacts without losing its shape or performance. This resilience makes it suitable for protective packaging and cushioning applications.

- Thermal Insulation: EPP foam provides excellent thermal insulation, making it an ideal material for applications that require strict temperature control.

- Chemical Resistance: EPP foam is resistant to a wide range of chemicals, including oils and solvents, which enhances its suitability for industrial applications.

- Environmental Sustainability: EPP foam is recyclable and can be reprocessed multiple times without significant degradation in performance, contributing to environmental sustainability.

The Drawbacks of Expanded Polypropylene:

- Cost: EPP foam can be more expensive than other types of foam, such as expanded polystyrene (EPS), due to its extended manufacturing process.

- UV Sensitivity: EPP foam can degrade when exposed to prolonged ultraviolet (UV) light, which may limit its use in outdoor applications unless protected or treated.

Interested in EPP Foam?

Get a Sample Sent Right to Your Business.

Common Applications of Expanded Polypropylene (EPP) Foam

- Automotive Applications: for impact protection in bumper cores, door panels, and headrests. It can also be used in vehicle HVAC components for noise reduction.

- Protective Packaging: EPP foam is ideal for protective packaging solutions for delicate and high-value items, offering excellent shock absorption and cushioning.

- Construction: EPP foam is used in construction for thermal insulation panels, providing energy efficiency and temperature control in buildings.

- Soundproofing: EPP foam’s sound absorption properties are utilized in soundproofing applications to reduce noise transmission.

- Sports and Leisure Equipment: EPP foam is often used in the production of helmets, protective gear, martial arts mats, and other sports equipment.

- Furniture: EPP foam is also used in furniture manufacturing for cushions and padding, providing comfort and durability.

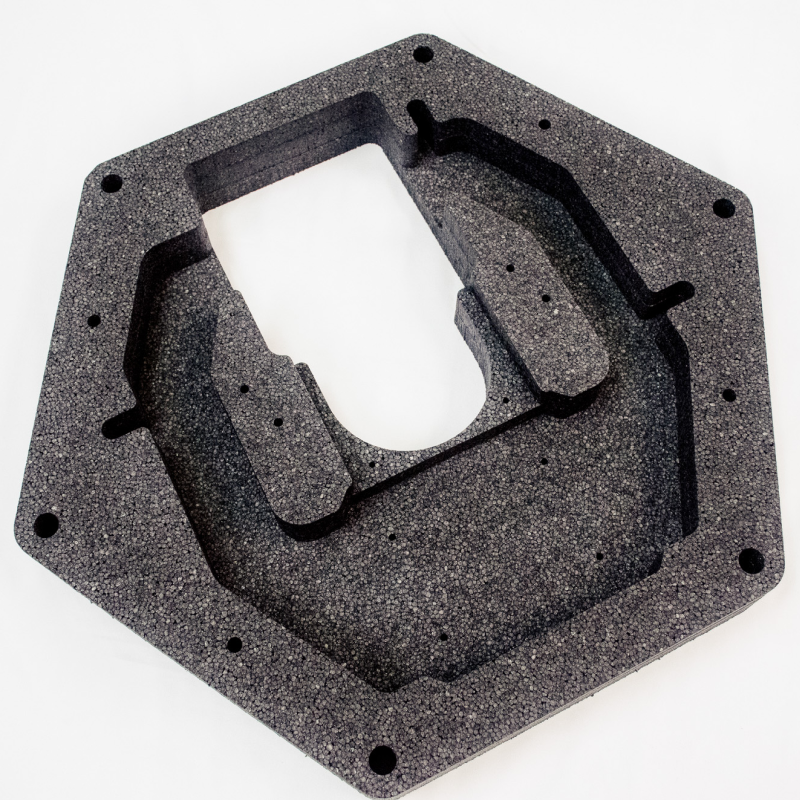

Amcon Foam Fabricates Custom EPP Foam Parts

Custom EPP foam packaging and parts offer several benefits, including precise fit, enhanced protection, and reduced shipping costs due to optimized space usage. At Amcon, we can help you choose the right fabrication method for your material, ensuring your custom foam products are well-suited for any application. From precision cutting to lamination and more, we are your custom foam fabrication partner.

Learn More About Our Custom Foam Fabrication Capabilities

Technical Documents for EPP Foam

Packaging Foam Material Specs

“We’ve been sourcing Amcon foam products to use in thousands of our client facilities for more than two decades. Their product quality and customer service are second to none.”

KYLE F.

President, Company Confidential