Electronic devices are some of the most complex devices to ship. Depending on the fragility of the item, they can be susceptible to static, vibration, extreme temperatures, and other environmental factors that are common in air, rail, road, and marine transport. To adequately protect these devices while in transit, foam is generally the material of choice. This is because many types of foam possess the properties necessary to shield electronic devices, parts, and equipment while in transit.

If you need to ship one of these devices, this is what you need to know when it comes to foam selection.

What Makes a Foam Ideal for Shipping Electronic Devices?

The best types of foam for shipping electronic devices have three major qualities.

#1: Anti-Static or Conductive Foam

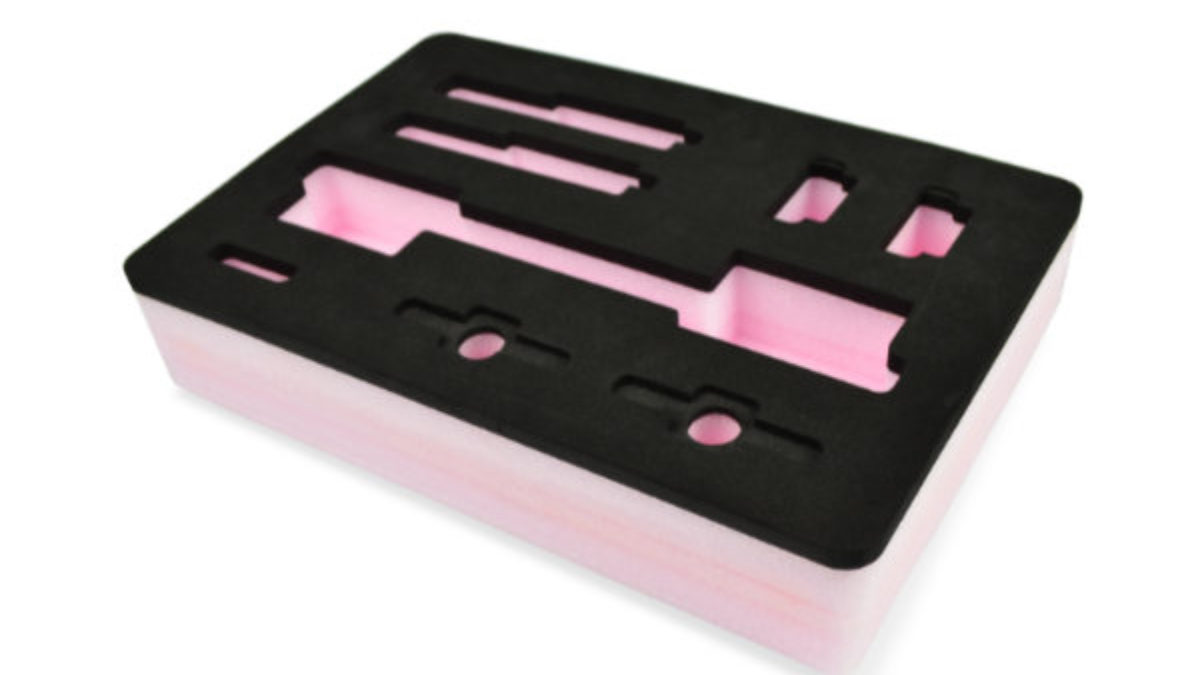

First, the foam should be anti-static (known as ESD foam). Anti-static foam acts as a sort of static shield for static sensitive items. The foam helps dissipate electrostatic charges that are easily generated by friction (which is common as items gently shift while in transit. These static charges can damage sensitive electronic devices and components. ESD foams are chemically treated with anti-static agents that give them a high surface resistance (usually 104 – 109). These types of foams are usually colored pink, but they can be dyed in a variety of colors for presentation purposes (usually for foam electronic device case inserts).

A second option is conductive foam, which is a type of polyethylene foam that is filled with carbon, giving it conductive properties. When an item is surrounded by conductive foam, the foam protects it by acting as a Faraday cage, meaning it blocks any electromagnetic fields from coming into contact with the item.

#2: Non-Abrasive Foam

Many electronic devices have sensitive parts that can be affected by abrasion. Other high-value electronic devices have delicate layers of paint on the outside of them can easily be scratched off due to small movements and vibrations that occur while in transit. To prevent damage to these sensitive devices, it’s necessary to use a non-abrasive foam. Non-abrasive foam will not scratch delicate surfaces should they brush against them.

#3: Packaging Material Standards

A good starting point when looking for anti-static foam for electronic devices is to ensure that it meets the necessary packaging standards. The best standard to look for is the EIA-541 Packaging Material Standards for ESD Sensitive Items, which applies to categories of electrostatic protective packaging materials that possess certain electrostatic properties, including:

- Preventing triboelectric charging (antistatic)

- Dissipating charge either by surface or volume conduction

- Acting as a shield against electrostatic fields

Consider the Size and Weight of the Item

Foam is generally open-cell or closed-cell. Polyurethane, an open-cell foam, is lighter and softer, which makes it more ideal for smaller, more sensitive products like circuit boards, CPUs, microprocessors, etc. This type of foam is available in sheets or as layered convoluted foam, also known as egg crate foam.

Cross-linked polyethylene, a closed-cell foam, is much more structurally rigid. This type of foam makes it more durable and tear–resistant. It also does not compress as easily as polyurethane, which makes it more ideal for larger, more bulky electronic items like computers, sound equipment, etc.

Choose the Right Foam AND the Right Foam Fabricator

The foam you choose is just as important as who you get it from. At Amcon, we developed distinct lines of conductive and anti-static foams that are ideal for all types of electronics and other static-sensitive products. We can help you choose the right foam and fabricate it so that it perfectly fits the item it needs to protect.