Felted foam is a widely used material that goes through a specific fabrication process to change its shape and density by volume. It also gives the foam material some new properties that allow it to be used in a variety of industrial and commercial foam applications.

What is felted foam? How is it fabricated? What are its uses? Here’s everything you need to know about felted foam and where it’s used.

What is Felted Foam and How is it Made?

Felted foam is foam that has been fabricated through a single axial heat and compression commercial process. The commercial foam felting fabrication process includes:

- Heating the platens to a specific temperature.

- Compressing the foam using the heated platens, which creates a hardened “skin” layer on the foam. An adjustable stop controls the platens and stops them once the desired foam dimension is achieved.

- Adding thin aluminum sheets to each side of the foam in the direction of the compression from the platens.

- Removing the foam and cooling it in an ambient environment.

Because open-cell polymer foams are cellular materials that are created through an extrusion foam process—where foaming agents are introduced to base materials to create void cell structures in the foam—air fills up the spaces within the material. This makes the foam soft and less dense.

Because open-cell polyurethane foams are cellular materials that are created through a liquid chemical reaction—where foaming agents are introduced to base materials to create void cell structures in the foam—air fills up these voids in the material. This makes the foam softer, flexible, resilient and less dense.

The felting process cures thick, soft foam materials like open-cell polyurethane (PU), allowing them to become denser during the fabrication process. Condensing these types of foams increases their surface area while maintaining their volume. This allows them to be used in specialty products and applications where they normally would not be used.

The Benefits of Felting Foam

Felted polyurethane foams have a few key benefits:

- They become firmer without adding volume

- They have an increased effective density

- Their highly restrictive cell structure makes them better suited for air and liquid filtration

- They have sound absorbing and vibration damping properties

Where Felted Foam is Used

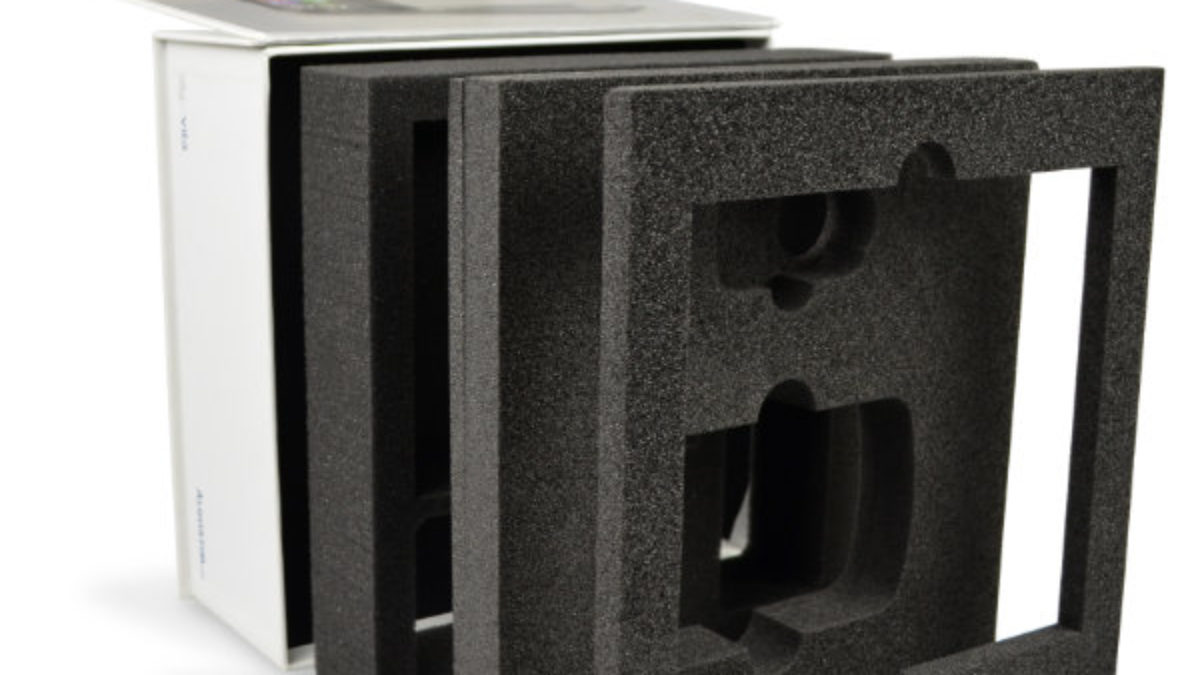

Compressed felted foam has a wide variety of uses and applications, specifically those in the commercial and industrial sectors. It’s used in appliances, ink printers, consumer electronics, automobiles, and filters.

Felted foam can be used for:

- Acoustic absorption

- Vibration dampening

- Thermal insulation

- Fluid and gas filtration

- Weatherstripping

Interested in using felted foam in your products or application? We can help. We fabricate various foams using the felting process to make them ideal for any application. Get in touch with Amcon today.