Healthcare Foam Fabrication

Applications

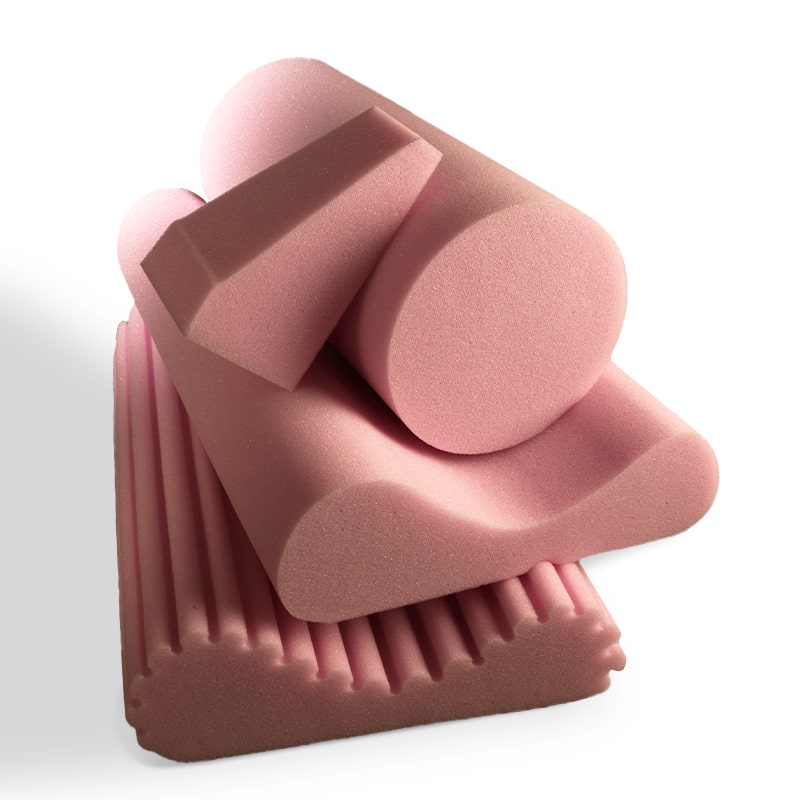

Foam to ensure the health of your project

When it comes to healthcare applications, your foam material’s performance is critical. At Amcon, we combine our extensive design and engineering expertise with specialized foams to meet your precise needs. Our foam has been used for medical devices and pharmaceutical packaging as well as in healthcare products, including:

- Hospital bed and cot cushions

- Lumbar rolls

- Specialized backrests

- Foam supports

- Neoprene braces

- Wheelchair wedges

- Custom heel lifts

We’re also a leading supplier of foam for the prosthetic and orthotics industry.

We offer the widest variety of foam for health care applications. We help you account for everything you need in a piece of foam: density and durability, foam compression and memory, and anti-microbial characteristics. Our medical foam options include:

- Expanded Polyethylene (EPE)

- Polyurethane (PU)

- Expanded Polypropylene (EPP)

- Polyethylene (PE)

- Expanded Polystyrene (EPS)

- Neoprene

With our extensive design experience and state-of-the-art manufacturing facilities, we have the ability to cut complex shapes, layer multiple types of foam, and can accommodate special inserts. You can count on Amcon for your critical foam needs. Most important to you, our greatest strength is our customer service—we are invested in the success of your project.

Healthcare Foam Solutions

Healthcare Medical Foam Packaging

We have extensive experience working with packaging for medical devices and pharmaceuticals. Foam is critical in medical packaging. It keeps sensitive devices and instruments safe and provides critical insulation for temperature sensitive items and medicines. We’ll help you select a foam that fits your specific needs and fabricate so that it provides the maximum protection during transit.

Healthcare and Medical Foam Cushioning

Medical cushioning requires complex customization to fabricate pieces of foam that support, cushion, and provide relief to patients. The durability, fungal resistance, and comfort of each piece of foam must also be considered. We help you choose the right foam for your cushioning application and shape it into custom pieces that perfectly fit your manufactured products, often combining two or more layered foam types.

Support Braces and Orthotics

Medical braces and orthotics require precise customization to achieve healthy medical outcomes for patients. We help you choose foam types that are washable, comfortable, and can withstand the stress of everyday use. These products often require complex construction and multiple foams, and we have the fabrication experience and technology to accommodate specialized short run orders, or long-term mass production.

Healthcare Foam Material Specs

Heathcare and Medical Foam Fabrication with Amcon

With 45+ years of foam fabrication experience and two manufacturing facilities that feature state-of-the-art fabrication equipment, Amcon is primed to help you design and create custom foam pieces for any medical application.

Everything begins with foam selection. There are many different medical applications for foam, and with many different classifications and grades of foam, we stock the right type of foam for any job. We can help you select the right type of foam based on the needs of your product and where it is used. From there, we fabricate custom pieces that perfectly match your product’s unique specifications.

We’re flexible and can accommodate anything from a specialized short run order to long-term mass production. As a full-service partner, we provide everything from foam fabrication to sewing, covering and private labeling in-house. We have the capabilities to take your project from a concept to a completed and packaged product. We also offer extremely fast prototyping, pricing and turnaround for production runs.

Make your next healthcare foam project a success with Amcon!

“We’ve been sourcing Amcon foam products to use in thousands of our client facilities for more than two decades. Their product quality and customer service are second to none.”

KYLE F.

President, Company Confidential