It’s not uncommon for some foam types to off-gas. Most of the time this is recognizable by a distinct smell that accompanies them, especially if they have been kept in an enclosed space for quite some time. The odor is caused by a process known as off-gassing. What is off-gassing? Why is it important for manufacturers to understand how it can affect their products?

The Chemical Process Behind Off-Gassing

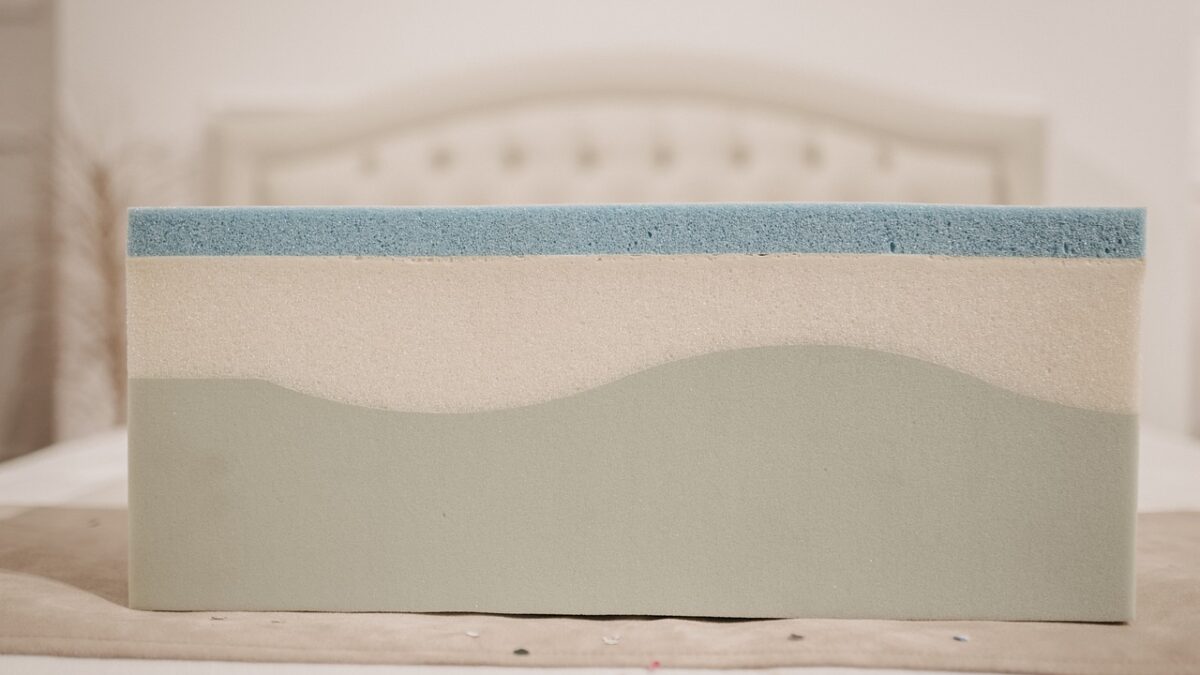

Off-gassing is caused by volatile organic compounds (VOCs) that are released into the air from pieces of foam, resulting in the familiar odor of “new products” when they are opened. These are a natural part of many polyurethane foams, although some foam types have more VOCs than others (even those that are considered “green materials”).

What exactly are VOCs? Volatile refers to a substance that can easily evaporate at normal temperatures, meaning it easily becomes a gas without any drastic temperature changes required. Organic, from a chemistry standpoint, means that a substance is carbon-based, and compound means that it is formulated using two or more different elements. The phrase off-gassing comes from the compound’s ability to release vapors into the air.

While off-gassing may sound like it’s dangerous to a person’s health, it generally is not, most of the chemicals in foam are rendered inert (inactive and harmless) during manufacturing and fabricating, but that doesn’t mean that a smell does not often remain.

When to Avoid Foams that Off Gas?

There are many applications where manufacturers and other businesses would want to use foams that limit off-gassing so as to avoid unpleasant odors in their products. When it comes to packaging foam applications, many businesses would prefer to use protective foam that limits off-gassing to provide a better product opening experience for their customers. Many manufacturers in the medical space also want to limit off-gassing in the foams they use as they can damage fragile and sensitive medical products and pharmaceuticals. These types of foams are also ideal for sales and demo cases because they provide a better presentation of products to potential customers.

What Types of Foams Limit Off-Gassing

While there is generally off-gassing in most types of foam, some heavily limit it because of the materials they are made out of as well as how they are made. Some foam options that limit off-gassing include:

- Beaded foams

- Expanded polystyrene (EP)

- Expanded polyethylene (EPE)

- Expanded polypropylene (EPP)

- Beaded polyethylene (BPE))

- Zotefoams (clean foams that are nitrogen expanded)

Need to limit off-gassing in your foam application? We can help you choose the right foam material. Contact us today to ask about our foam options or to receive a sample.