Three important considerations when selecting a foam material for an application are its density, weight, and firmness. These are often grouped together because they are related to how a foam performs under certain uses, but they are very different descriptors of three very different foam properties.

What’s the difference between foam density, weight, and firmness? Find out what each means in terms of a foam’s usefulness to your application.

What is Foam Density?

Foam density measures how dense the material is per cubic foot. Density is measured by using mass per unit volume; it’s calculated by taking the mass of the foam and dividing it by its volume. In terms of foam density, the measurement is pounds per cubic foot (lbs./ft3). This is measured using ASTM D-3574-17 standard testing methods.

While denser foams are heavier (when compared to another piece of foam of the same size), the measurement is not to be confused with the foam’s material weight (see below for the definition of foam weight).

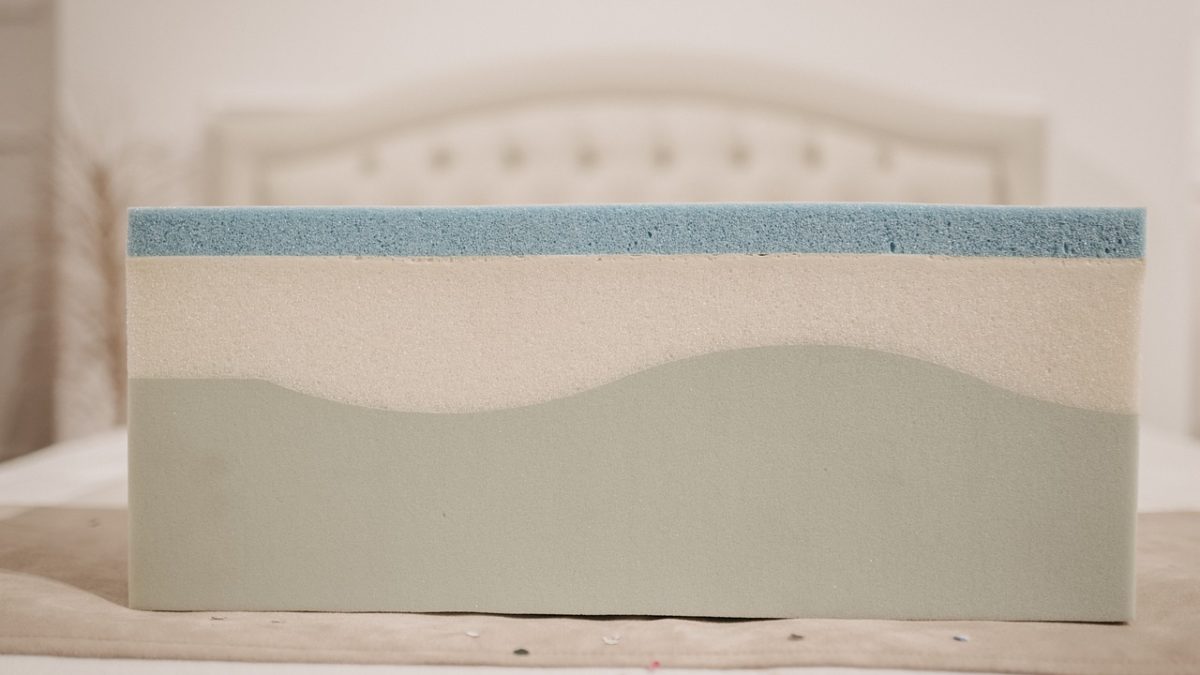

Foam density is generally tied to the durability and comfort of a piece of foam. Denser foams are able to resist greater amounts of pressure and compression over time, making them longer lasting materials. Less dense pieces of foam inevitably begin to sag and lose their shape over time, while more dense foams will not deteriorate as quickly. When it comes to comfort (as with foams used in cushioning applications), it’s important to balance the density of the piece of foam based on the specific application. If your foam is too dense, it won’t be as comfortable and may feel too hard (see more on foam firmness below). If the foam is not dense enough, it can collapse under the weight of a person, making the cushioning less comfortable and supportive.

When it comes to shipping and foam packaging applications, foam density changes which types of products the piece of foam will best protect. Less dense foams are generally used to protect smaller, more delicate items, while denser foams are more suitable for larger and bulky items.

What is Foam Weight?

Foam weight is a simple measurement of how much the entire piece of foam weighs, as opposed to its mass per cubic foot (see above for foam density). Why is the weight of foam important? In many cases, it comes down to pricing. If you use heavier pieces of foam in a product, it will cost more to produce and ship. The same is true for foam packaging. Heavier pieces of foam will add to the shipping costs for your products. As you increase the thickness and size of a piece of foam, you will increase its weight. Make sure you balance the size of a piece of foam with its weight and density to achieve the desired outcome for your application.

What is Foam Firmness?

Foam firmness refers to the piece of foam’s ability to resist compression when pressure is applied to it. While denser foams are generally firmer than foams with a lower density, this isn’t always the case. Density does not necessarily equate to firmness, and the terms should not be confused with one another. A foam’s firmness is measured in indent force deflection (IFD), which is evaluated using ASTM D-3574-17 standard testing methods. The foam’s deflection is noted when the piece of foam compresses by 25 percent when a force is applied to it. An ILD number is then assigned to it; the higher the ILD number, the firmer the foam.

Foam firmness is important, particularly in cushioning applications. Foam mattress, as an example, are particularly in demand. Foams that are firmer can support more weight without making the person uncomfortable.

When choosing a foam for your application, we can help you find the most effective density, weight, and firmness ratios, getting you the best performance. Get in touch with our foam experts today.