Vibration is a constant force across a wide range of environments, from the gentle hum of server equipment to the heavy oscillation of industrial machinery. Left unmanaged, the impact of vibrations can cause premature wear, accelerated fatigue, and damage to delicate components. It can also generate vibration-induced noise that affects product quality and the overall user experience. Protecting sensitive contents from vibration isn’t just a maintenance concern; it’s a key factor in the design of products that must operate reliably over long periods of time.

Vibration Protection: Why the Right Foam Makes All the Difference

Effective vibration control focuses on either absorbing and dissipating structural energy or creating an insulative barrier that prevents vibration transfer. Engineered foam materials take this one step further by blocking the movement of a structural sound wave, reducing mechanical oscillation, and improving impact absorption across a range of environments.

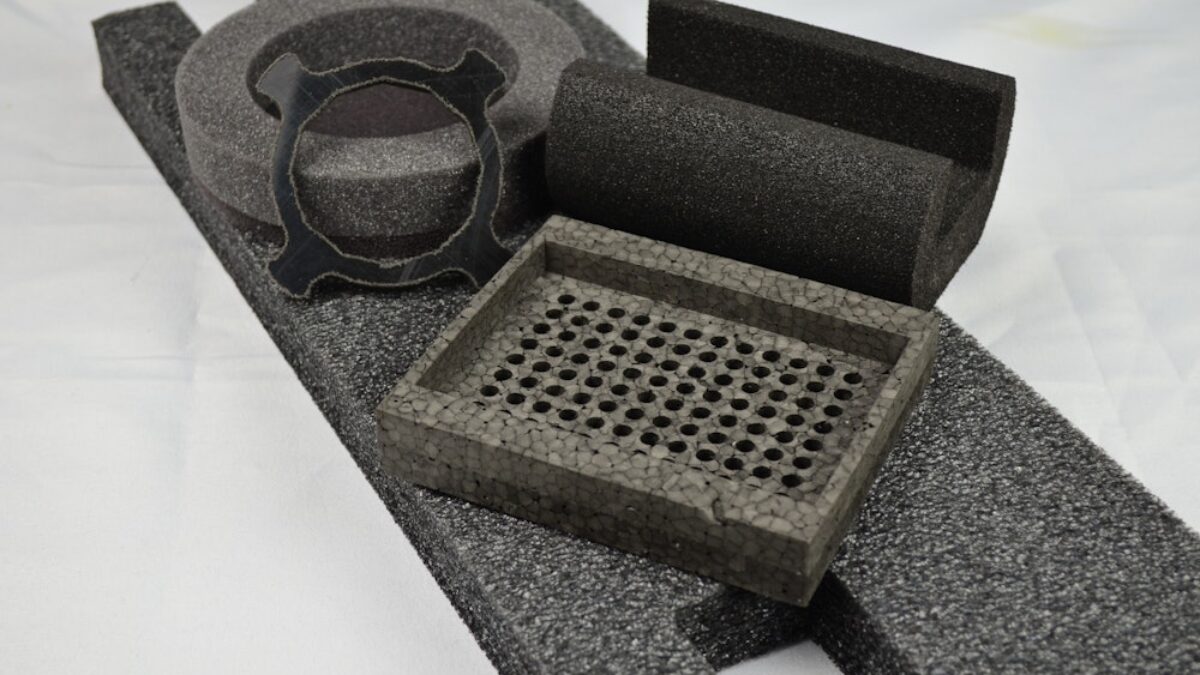

These foams are engineered for excellent resistance to compression, deformation, and repeated mechanical stress. While they may appear simple, their cellular structures provide advanced vibration damping, noise reduction, and additional vibration management. For many industries, foam offers a proven, long-term solution that performs reliably in manufacturing, transportation, consumer goods, instrumentation, and Music & Media equipment.

Polyethylene (PE), Expanded Polyethylene (EPE), XLPE and Expanded Polypropylene (EPP)Foam: Structural Isolation for Heavier Components

When vibration must be controlled without sacrificing structural integrity, PE and XLPE are among the strongest performers. These closed-cell foams provide durable isolation for heavier, rigid components and deliver excellent resistance to creep, stress relaxation, and compression over time. By resisting structure-borne vibration and breaking up the path of sound, these foams prevent mechanical energy from transferring into the product.

Their dense, resilient composition also enhances impact absorption, making them ideal for protecting heavy or sensitive components during handling, transport, or operation. Because they maintain dimensional accuracy under load, PE and XLPE are well suited for vibration management applications that demand both cushioning and stability.

Key Characteristics of Polyethylene (PE), Expanded Polyethylene (EPE), XLPE and Expanded Polypropylene (E)

1. High Load-Bearing Capacity

Provides stable support with minimal deflection that is critical for heavy machinery, structural assemblies, and large equipment.

2. Superior Durability

Offers excellent resistance to moisture, tearing, chemicals, and abrasion, ensuring vibration protection remains consistent in demanding conditions.

3. Acoustic and Thermal Performance

Their closed-cell structure reduces the transmission of sound, dampens the movement of a structural sound wave, supports low-frequency noise reduction, and creates a reliable thermal and insulative barrier.

Common Applications for Polyethylene (PE), Expanded Polyethylene (EPE), XLPE and Expanded Polypropylene (EPP) Vibration Foam

- Industrial Machinery

Used beneath presses, generators, and lathes as durable vibration pads that reduce structural vibration transfer. - Transportation & Logistics

Protects heavy items and keeps contents from vibration during transit with strong impact absorption. - Automotive Components

Supports gaskets, seals, and mounting blocks to prevent structure-borne vibration and improve ride comfort. - HVAC Systems

Installed beneath compressors and fans to minimize vibration-induced noise and mechanical oscillation. - Field Equipment & Tool Cases

Provides shock and vibration control for tools, instruments, and portable, battery-operated products.

Choose the Right Foam for Reliable Vibration Isolation

Whether you’re protecting precision instruments, stabilizing heavy machinery, or designing acoustic solutions for Music & Media, the right foam helps control vibration, improve performance, and extend product lifespan.

At Amcon Foam, we evaluate material behavior, density, geometry, and environmental conditions to engineer the right solution.

We support CNC routing, waterjet cutting, die cutting, contour cutting, and skiving to ensure every vibration-control component is cut, shaped, layered, and optimized to your exact specifications. We deliver excellent performance where it matters most.

If you need guidance selecting the ideal foam for your vibration-control application, our engineering team is here to help.