Foam permeability is largely determined by the material’s cell structure, which can be either open-cell or closed-cell. It’s one of the many factors you should understand when choosing the right foam for your application.

What Is Permeability in Foam?

Permeability refers to the ability of a material to allow the passage of air, water, vapor, or gases through its structure. In foams, this is determined by the size, shape, and connectivity of the individual cells that make up the material.

The permeability of foam affects how well it functions in moisture control, impact resistance, filtration, and thermal insulation. Some foams are designed to allow airflow and fluid movement, while others act as complete barriers to water, air, or chemical exposure.

Industries that rely on high-permeability foams include:

- Filtration and HVAC: open-cell foams allow air and liquid to flow through, making them ideal for air and fluid filtration.

- Medical and Healthcare: permeable foams are used in wound care and padding, where moisture control is necessary.

On the other hand, industries that require low-permeability foams include:

- Shipping and Packaging: closed-cell foams prevent moisture and air infiltration, protecting sensitive items from damage.

- Marine and Aerospace: low-permeability foams prevent water ingress, ensuring durability in extreme environments.

Understanding how permeability impacts foam performance is essential when choosing the right material for a specific application.

How Permeability Impacts Foam Performance

The permeability of foam affects multiple functional aspects, including:

Moisture Resistance

Foams with low permeability (closed-cell foams) are ideal for waterproofing and moisture resistance in applications such as marine insulation, flotation devices, and packaging for moisture-sensitive products. High-permeability foams (open-cell foams) absorb and distribute moisture, making them useful in medical dressings, cushions, and filtration applications.

Airflow and Breathability

Foams with high permeability allow for airflow, which is beneficial in cushioning applications, HVAC filters, and ventilation systems. Closed-cell foams, by contrast, provide airtight seals for industrial gaskets, automotive components, and weatherproofing materials.

Impact Absorption and Cushioning

Open-cell foams compress more easily, allowing them to absorb shock and vibration effectively. This makes them ideal for protective padding and shock-absorbing packaging. Closed-cell foams, on the other hand, offer greater rigidity and do not deform as easily under pressure, making them better suited for load-bearing applications.

Insulation and Thermal Protection

Permeability also affects the thermal conductivity of foam materials. Closed-cell foams trap air within their structure, providing superior thermal insulation for construction, refrigeration, and aerospace applications. Open-cell foams allow heat and air to move freely, making them better suited for applications where breathability and moisture management are required.

The Differences in Permeability Between Open and Closed Cell Foams

Foams are broadly classified into open-cell and closed-cell structures, which significantly influence their permeability.

Open-Cell Foam Permeability

Open-cell foams have a porous structure where the individual cells are not completely enclosed, allowing air, water, and other substances to pass through.

The characteristics of open-cell foam permeability include:

- Highly breathable – ideal for applications requiring air circulation.

- Absorbs liquids – can retain water, making them useful in medical and filtration applications.

- Soft and compressible – offers excellent cushioning and shock absorption.

- Lower density – typically lighter and more flexible than closed-cell foams.

The applications for open-cell foams include:

- Medical dressings and padding – allows air circulation and moisture management.

- Seating and cushioning – resiliency and comfort properties.

- Soundproofing – used in acoustic panels for noise reduction.

- Packaging materials – absorbs impacts and cushions delicate equipment.

- Filtration systems – used in air and liquid filters.

Closed-Cell Foam Permeability

Closed-cell foams have fully enclosed cells that prevent the passage of air, water, and gases.

The characteristics of closed-cell foam permeability include:

- Low permeability – provides excellent moisture resistance and insulation.

- Rigid and durable – more resistant to compression and impact.

- High-density structure – offers better load-bearing capabilities.

- Better thermal performance – used in applications requiring heat and cold resistance.

The applications for closed-cell foams include:

- Marine flotation devices – resistant to water absorption.

- Thermal insulation – used in refrigeration, HVAC systems, and aerospace.

- Automotive seals and gaskets – creates an airtight and waterproof seal.

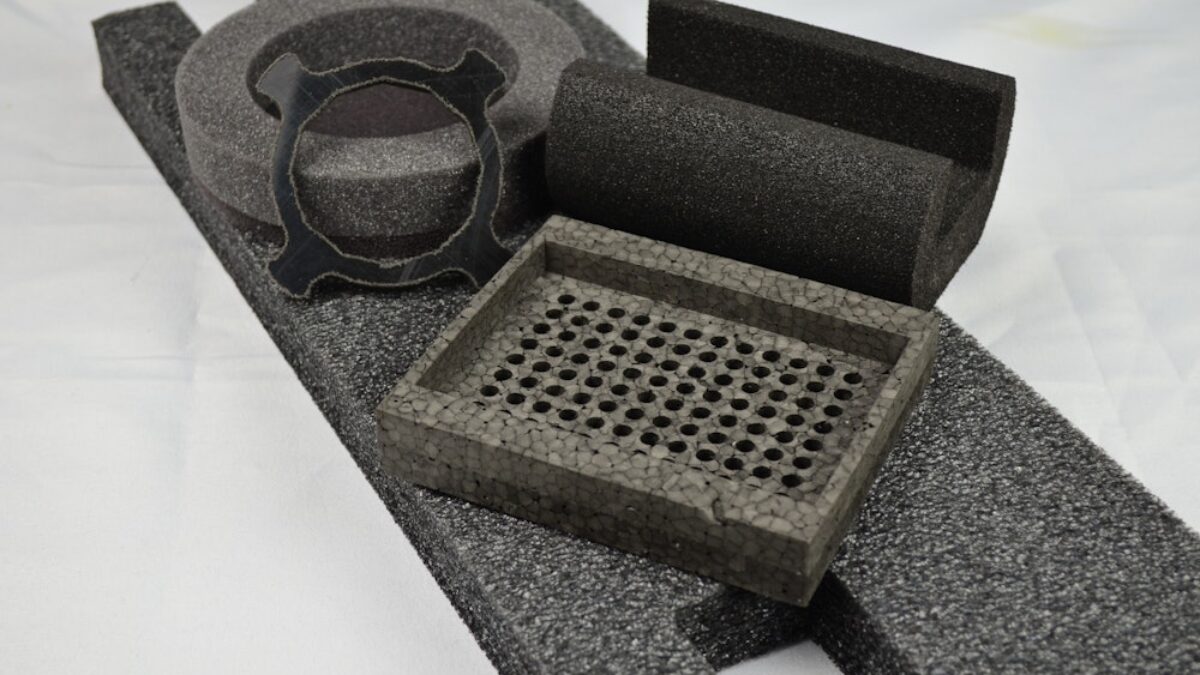

- Protective cases and industrial packaging – shields sensitive equipment from damage.

- General packaging for shipping and e-commerce.

How to Choose the Right Foam Based on Permeability

When selecting foam for an application, consider the required level of permeability:

Do you need moisture resistance? Choose a closed-cell foam for waterproofing and outdoor applications. Do you need breathability? Open-cell foams are better for ventilation, cushioning, and moisture management. Will the foam be exposed to pressure or heavy loads? Closed-cell foams offer better load-bearing capacity. Does your application require soundproofing? Open-cell foams work better for acoustic dampening.

Permeability Matters in Foam Selection

Choosing the right foam material isn’t just about density or cost, it’s about understanding how permeability affects functionality. Whether you need highly breathable, impact-absorbing open-cell foams or rigid, moisture-resistant closed-cell foams, knowing their permeability properties is essential for achieving the best performance in your application.

Need high or low permeability foams for your application? Get in touch with Amcon today to talk about your application.