Identifying the porosity of a piece of foam is critical to determining whether it can be used in a particular application. Foams that are considered porous foams behave very differently than those that are non-porous, so looking at the porosity of a type of foam will dictate if it can be used in applications like gasketing, filtering, etc. What is porosity, and how does it determine the uses of foam materials?

What is Porosity in Foam?

Porosity in foam describes how many pores—small openings on the surface of the material—are present within the material. Greater porosity means more pores are present. Foams that are high in pores are more permeable, which means they will allow more liquids and gases to pass through them. Porous foam tends to also be less dense and will compress more than non-porous foam. They also have a high surface area to volume ratio and an open-cell structure.

Less porous foams tend to be classified as closed-cell, meaning that the cells of the material are more densely packed together and enclosed. This makes the foam less permeable and more dense.

Why Does Foam Porosity Matter?

Foam porosity matters when considering which materials to use for many applications, but two of the more important are gasketing and filtration. Most foams intended for filtration applications are subjected to a process known as reticulation – reticulation is a post process in foam manufacturing that removes the window membranes of the cell. This opens the cell structure of the foam up and creates a true PPI foam.

Filters need to allow liquids and air to pass through the material, capturing solids and particles. This requires an open-cell, porous foam. These types of filter foams include reticulated foams, ether polyurethane foam, and ester polyurethane foam.

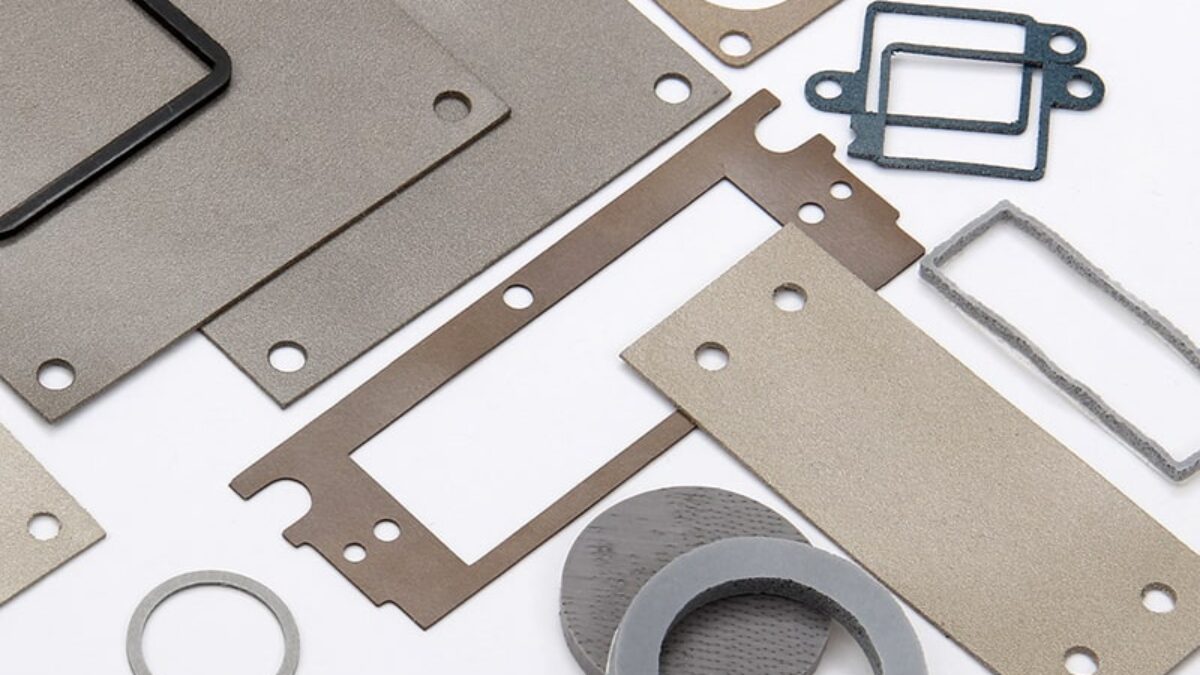

Since gasketing requires either air or liquids to be prevented from passing through a piece of material, it’s essential to choose porous or non-porous foams, based on your needs. If your gasketing needs involve blocking liquids and air, use a denser, non-porous foam. If your gasketing needs to allow air to pass through, but prevent liquids from moving through the material, a foam with a greater porosity will be needed.

The best types of foams to use for gasketing applications include:

- Neoprene foam

- Silicone foam

- EPDM

- Urethane

- Polyethylene

- Polypropylene

Measuring Porosity in Foam

Porosity in foam is measured using PPI (pores per inch). This measures the cell density in the piece of foam. The standard range is 10-80 PPI, with 10 meaning that the pores are large and the foam is open to filtration, and 80 meaning that the cells are small, closed, and much more suited to gasketing and sealing applications. When looking at a piece of foam for any of these applications, PPI will be the primary indicator of its effectiveness.

Need foam for sealing, gasketing, filtration, or any other application? Get in touch with the foam experts at Amcon today.