When it comes to shipping valuable or delicate items, there’s always a concern about damage, especially when it comes to scratching the surface of those items. While foam packaging is important in keeping items intact, it’s equally as important to choose a foam packaging material that is non-abrasive. Why should packaging materials be non-abrasive, and what are the best types of foam that offer non-abrasive protection?

The Importance of Non-Abrasive Packaging Materials

Non-abrasive packaging materials not only ensure products maintain their integrity and arrive intact during shipping, but they also protecting delicate surfaces from scratches, scuffs, and other forms of damage during shipping. These materials help maintain the pristine condition of products, which is particularly important for items with high value.

Using non-abrasive packaging materials minimizes the risk of products arriving damaged, leading to higher customer satisfaction. Happy customers are more likely to become repeat buyers and recommend your brand to others. Consistently delivering products in excellent condition also enhances your brand’s reputation, demonstrating your commitment to quality and attention to detail.

What Kinds of Items Should Be Shipped in Non-Abrasive Materials

Certain items are particularly susceptible to damage from abrasive packaging materials. Here are some examples of products that should be shipped with non-abrasive protection:

- Electronics: screens, monitors, and other sensitive devices require packaging that won’t scratch or damage their delicate surfaces.

- Automotive Parts: painted and polished components need protection to maintain their appearance and functionality.

- Furniture: items with varnished or painted finishes must be protected from scratches and scuffs during transit.

- Glassware: fragile and delicate glass items need cushioning that won’t add additional risk of surface damage.

- Jewelry and Watches: high-value items with fine finishes require non-abrasive packaging to maintain their pristine condition.

- Artwork: paintings, sculptures, and other artworks need careful handling and non-abrasive materials to preserve their value and integrity.

- Military: many military products have Class A surfaces, which need to be protected with non-abrasive foam.

What Are Class A Surfaces?

Class A surfaces refer to high-quality, visible surfaces that must remain flawless and free from any imperfections. These surfaces are often found in luxury goods and high-end products. Common examples of Class A surfaces include automotive body panels, high-end electronics, luxury goods, and premium appliances.

Protecting Class A surfaces is critical because any damage can significantly impact the item’s aesthetic appeal and value. Non-abrasive packaging materials are essential for safeguarding these surfaces during shipping.

Which Types of Foam Are Non-Abrasive?

Several types of foam are ideal for non-abrasive packaging, offering excellent protection without causing damage to delicate surfaces:

Expanded Polyethylene (EPE) Foam

Expanded Polyethylene foam has a closed-cell structure. It is also made with expanded foam beads utilizing pressure and steam. The result is a foam that is lightweight, provides omnidirectional protection and excellent resistance to moisture. This foam is ideal for packaging electronics, glassware, and delicate instruments, providing a protective barrier that prevents scratches and damage.

Polyurethane Foam

Polyurethane foam is soft, flexible, and available in various densities to suit different protection needs. It’s suitable for cushioning fragile items and providing surface protection, ensuring that products remain undamaged during transit.

Cross-Linked Polyethylene Foam

This foam has a fine cell structure, excellent surface protection, and chemical resistance. It’s used for high-end electronics, automotive parts, and medical devices, providing reliable protection against abrasion.

EVA Foam (Ethylene Vinyl Acetate)

EVA foam is soft, flexible, and durable, making it an excellent choice for packaging. It’s often used for luxury items, sports equipment, and protective cases, offering non-abrasive protection that keeps items safe.

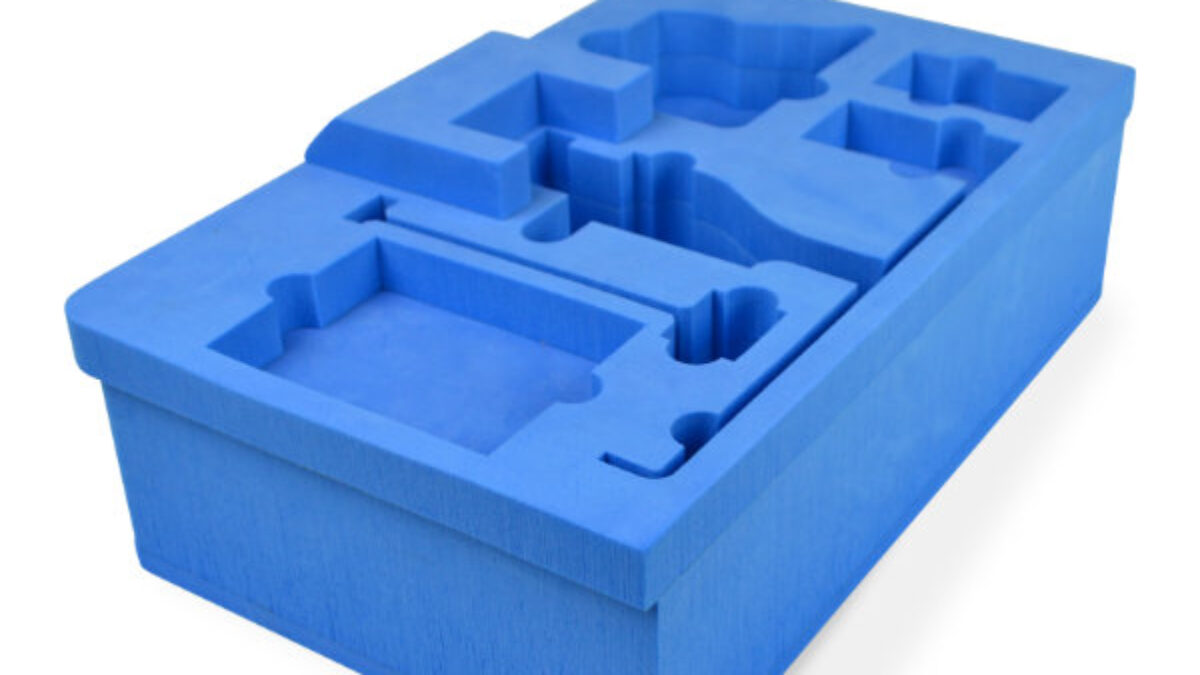

Get Custom Fabricated Foams for Your Products

Using non-abrasive packaging materials is essential for protecting delicate and high-value items during shipping. At Amcon, we can help you choose the right materials to ensure that your products arrive in perfect condition, leading to higher customer satisfaction and a stronger brand reputation. We can also fabricate those foam pieces to custom fit your products, protecting them with the best non-abrasive packaging materials and severely reducing the number of damages and returns you have to deal with.

Get Custom Foam Parts for Your Products. Contact Amcon Foam Today for a Quote, Foam Sample, or Anything Else You Need.