Thermal conductivity is a common property many applications require of foam materials, particularly for those that need proper insulation, heat management, or thermal protection. By understanding how thermal conductivity impacts foam performance, you can select the right materials for your specific needs.

What Is Thermal Conductivity?

Thermal conductivity refers to the ability of a material to conduct heat. It is measured in units of watts per meter-kelvin (W/m·K) and indicates how efficiently heat energy passes through the material. In simpler terms, materials with high thermal conductivity transfer heat quickly, while those with low thermal conductivity act as insulators, slowing down heat transfer.

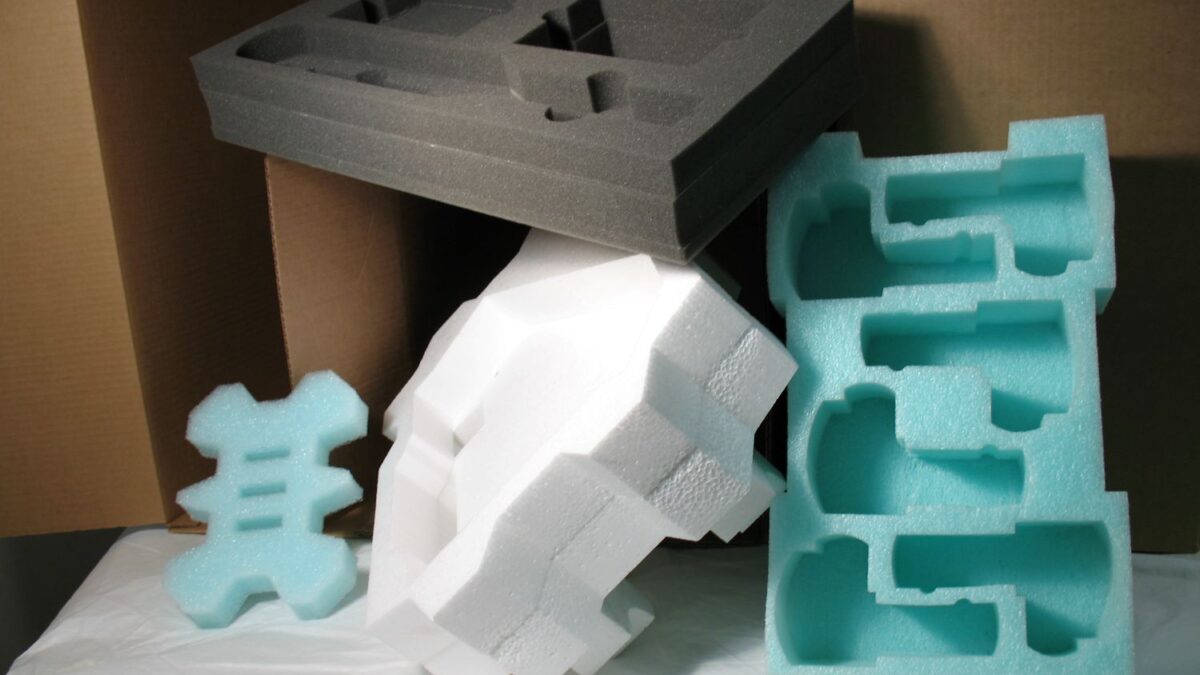

Thermal conductivity in a piece of foam is influenced by factors like cell structure (open-cell vs. closed-cell), density, and the composition of the material. Foams are often chosen for their insulating properties, which depend on their ability to resist heat transfer effectively. Understanding this property is vital for applications where temperature control is critical, such as in HVAC systems, packaging, automotive components, and construction.

How Does Thermal Conductivity Impact Foam Performance?

The thermal conductivity of a foam significantly affects its performance in various applications. Here’s how:

1. Insulation Efficiency

Foams with low thermal conductivity are excellent insulators, making them ideal for applications where maintaining temperature is crucial, such as refrigerated transport, HVAC ducting, and building insulation. These foams help reduce energy consumption by minimizing heat loss or gain.

2. Heat Management

In electronic devices or industrial settings, foams with controlled thermal conductivity are used to dissipate heat, protecting sensitive components from overheating. This is especially important in thermal interface materials (TIMs) and gaskets.

3. Comfort and Safety

Foams with appropriate thermal conductivity levels enhance comfort in applications like seating and bedding by regulating heat transfer between the body and the surface. They also play a role in personal protective equipment, where thermal resistance is essential.

4. Application-Specific Performance

For some industries, foams with higher thermal conductivity are preferred to transfer heat effectively. This is common in applications like heat exchangers or thermal shielding in aerospace and automotive industries.

Which Foams Have a Low Thermal Conductivity?

Expanded Polystyrene (EPS)

Expanded Polystyrene (EPS) is a lightweight, rigid, closed-cell foam known for its exceptional thermal insulation properties. Its low density and air-filled cells make it highly effective at reducing heat transfer. EPS is widely used in building insulation, packaging, and refrigerated containers. It is a cost-effective solution for applications requiring reliable thermal resistance.

Extruded Polystyrene (XPS)

Extruded Polystyrene (XPS) foam is a denser and more moisture-resistant version of polystyrene. Its uniform closed-cell structure provides excellent thermal performance, making it a go-to material for foundations, building insulation, and structural applications. XPS is suitable for environments where durability and thermal insulation are critical.

Polyurethane (PU) Foam

Polyurethane foam is a versatile material available in both flexible and rigid forms. Its closed-cell structure provides excellent thermal insulation. PU foam is widely used in HVAC insulation, refrigeration systems, and construction as a thermal barrier. Its adaptability and thermal performance make it an ideal choice for energy-efficient designs.

Crosslinked Polyethylene (XLPE) Foam

Crosslinked Polyethylene (XLPE) foam is a closed-cell material offering excellent thermal resistance, moisture resistance, and cushioning properties. Its thermal conductivity makes it suitable for pipe insulation, HVAC systems, and medical device applications. XLPE foam’s combination of thermal insulation and durability ensures consistent performance across various industries.

Polypropylene Foam

Polypropylene foam is a lightweight, semi-rigid material offering good thermal insulation and impact resistance. Its versatility makes it popular in packaging, automotive interiors, and HVAC systems. Polypropylene foam provides reliable thermal resistance for applications where weight and resilience are important.

PVC Foam

PVC foam is a closed-cell material that combines thermal insulation with resistance to moisture and chemicals. It is commonly used in signage, marine applications, and building insulation. PVC foam is a durable and adaptable option for environments requiring lightweight and reliable thermal performance.

Choosing the Right Foam for Your Application

Selecting the right foam with appropriate thermal conductivity depends on the application requirements. Here are some considerations:

- Low Thermal Conductivity: ideal for insulation in HVAC systems, refrigerators, and building materials. Examples include standard polyethylene or polyurethane foams.

- Moderate Thermal Conductivity: suitable for seating, bedding, or comfort applications where heat management is secondary.

- High Thermal Conductivity: essential for electronics, aerospace, and industrial uses where heat dissipation is critical.

Is thermal conductivity important for your application? Get in touch with us today to find the right foam material.