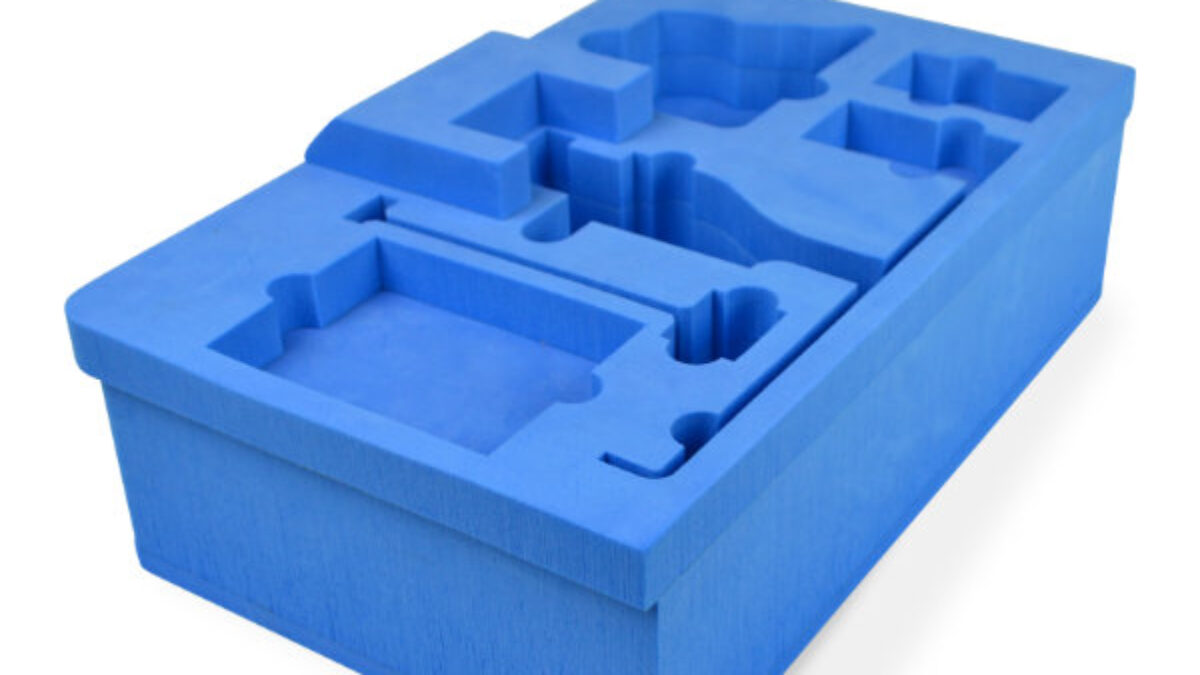

At Amcon, we understand the complexities of building custom case inserts and cases for a wide variety of products. Whether you need a prototype insert or thousands of pieces, we can help. Our experience with materials and construction techniques allows us to build a complete case solution for any item. It all begins with choosing the best foam for the application.

What do you need to know about creating a custom foam case for your products?

What to Consider When Choosing a Case Foam

Whether you’re protecting high-value electronics, medical devices, or anything else, it’s important to consider the properties of your products and what they need to be shielded against. When choosing a foam for your case inserts, consider which types of protection you need to provide. Do you need:

- Fire resistant, anti-static and MIL-SPEC foam

- ESD foam for sensitive electronic parts and deliveries

- Non-abrasive form for painted parts

- Food safe materials

- Foam for fragile items or heavy shock absorbers

- Cost effective materials

- Water or moisture resistance

- High- or low-density foams

Which foam is right for your case? There are several types of foams that can be right for your application depending on the products you are storing in your custom cases.

Polyethylene (PE)

Polyethylene is a closed cell foam that is ideal for storing and shipping heavy and bulky items because of its ability to withstand high impacts and dampen vibrations. The material will not compress as easily as other types of foam, meaning less material can be used to provide high amounts of protection. It’s also non-abrasive and resistant to dusting, mold, chemicals, and moisture.

Expanded Polyethylene (EPE) Foam

EPE is a molded thermoplastic foam that is semi-rigid, making it denser and more resilient when exposed to shock impacts. It has less concavity and shrinkage while being cut, allowing for cleaner and more precise die cutting. This makes it a very desirable foam for custom case inserts that have complex shapes. It shares many characteristics with polyethylene foam—being non-abrasive and resistant to dusting, mold, chemicals, and moisture.

The main difference between PE and EPE foams is in the manufacturing process. Polyethylene is generally made via extrusion, while EPE is created through the expansion of polyethylene beads. Polyethylene is able to be produced in a wide range of densities, while EPE typically has a lower density.

Polyurethane (PU) Foam

Polyurethane is a lightweight open cell foam that is ideal for storing and shipping lighter and fragile objects that require more delicate protection. The foam is available in a variety of densities and can be custom cut (or die cut) to fit products of any shape. Polyurethane also maintains its shape over time, ensuring long-lasting protection for the items it protects. It also has high resistances to chemicals, mold, UV radiation, and abrasion.

Expanded Polypropylene (EPP)

EPP is a closed cell molded foam that is made up of expanded beads that are fused together into a block. The material can be CNC cut and die cut to provide custom protection when used as a case insert. Expanded polypropylene is especially known for its stiffness when compared to other foam options like polyethylene. It performs well in drop tests and withstands impacts from any angle. It also provides good thermal protection, chemical resistance, and bacteria growth.

Neoprene

Considered an elastomer, neoprene is a foam that is similar to rubber. It’s flexible, durable, and soft, making it ideal for protecting a wide variety of items from different industries. The foam can withstand heavy shocks and compression, all while dampening sounds and vibrations that can harm items. It also provides ample weather resistance, chemical resistance, and thermal insulation. It’s a versatile material that lends itself to many protective applications.

From foam selection to full customization and more, we can help you build a protective case for your items from the ground up. Let’s get started on your next project today.