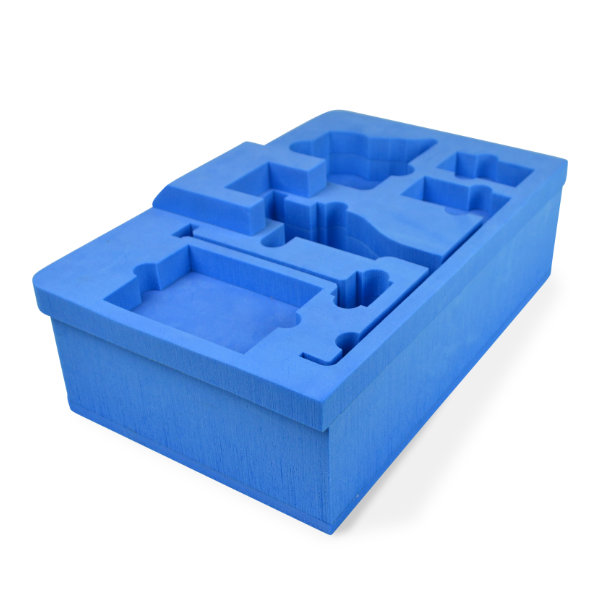

Protective Foam Case Inserts

Protection And Presentation All In One Case

Whether you’re looking to protect sensitive electronics from static, transport high-value medical devices, or achieve a premier look for sales and demo kits, Amcon has the design and manufacturing experience to help you customize the best foam case insert for your product. Our massive selection of foam and comprehensive fabrication capabilities allow us to customize foam case inserts based on the exact specifications of your product, providing complete protection and a presentation that is second to none.

Creating the ideal foam case insert is a complex process. We make it easy for you. Simply provide us with a sample of your product or part and we’ll design and fabricate the best protection for it. We offer end-to-end guidance that includes design, finishing, and foam/case selection. Whether you need a single foam case insert or thousands, we are invested in the success of your project.

High Value Electronics

Medical Equipment

Guns & Military

Sales Demo Cases

Custom Foam Case Insert Options

- Choose Your Material Type, Color and Grade

Hundreds of foam types provide you with the flexibility to choose the right material for your case. From static control foam for electronic equipment to non-abrasive foam for painted parts, we have it all. - Customize Your Foam Case Insert

Our state-of-the-art facilities have the capability to completely customize your foam case insert. We use over a dozen routing, cutting, and tooling techniques to achieve the best look and fit at minimum cost. - Enhance with Surface Treatments

To finalize and improve the appearance of your products, we employ many surface treatments (including flocking, etc.), allowing you to achieve the most aesthetically pleasing presentation possible. - Add ESD Protection

We have a wide variety of ESD and anti-static foam options to protect sensitive electronic and other high-value devices. These custom cut foams will protect your inventory while in transit to, from, and throughout any facility.

We Work With All Leading Case Manufacturers