Industrial Foam Fabrication

Foam for Filters, Gaskets, Sound Abatement, and More

Foams required for filters, gaskets, and other industrial settings and parts must be able to withstand the harsh factors present in these types of environments. At Amcon, we understand the unique characteristics of a wide variety of foams and how they can perform in HVAC systems, pumps, pipes and other industrial applications. Our massive selection of foam, comprehensive fabrication capabilities, and industrial knowledge allow us to customize the right foam parts for your products.

We also offer a comprehensive range of in-house solutions that include fast prototyping, pricing, and timely turnaround for production runs. Whether you are in the design phase or ready for mass production, we can help you bring your next project to completion.

We have the most comprehensive inventory offerings in the foam fabrication market. Everything you need to complete your project, from material management to distribution, local deliveries, freight management, and delivery coordination, we have the capability and materials to do it all.

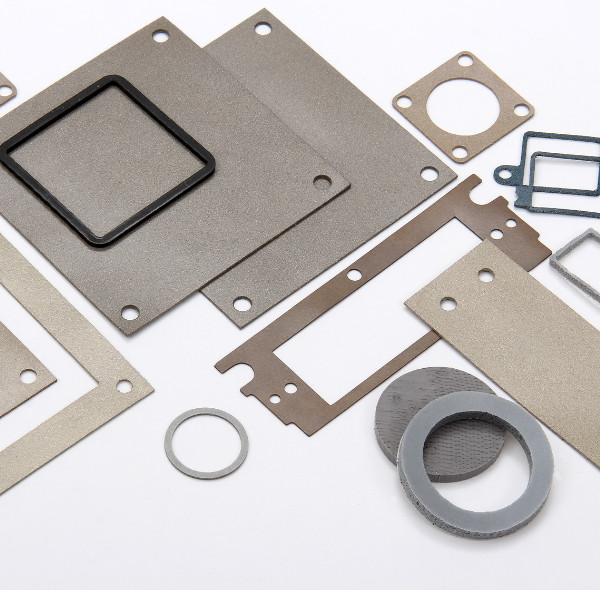

Foam & Neoprene Gaskets

Filter Foam

Sound Abatement

Custom Industrial Foam Options

- Industrial Filter Foam

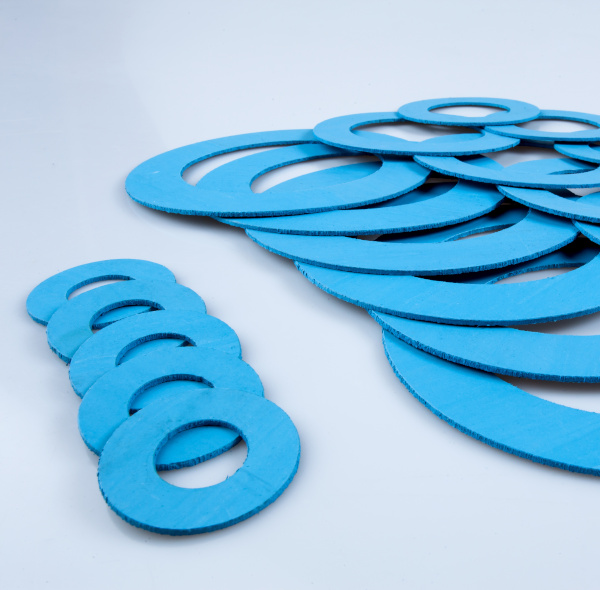

We supply filter foams in a wide range of porosities. Any size and shape can be achieved for HVAC or any other air or liquid filtering application. From open-celled to closed-cell foams, we can help you choose the proper material for HEPA performance. - Industrial Foam for Gaskets

We manufacture gaskets and combination filters using a wide variety of open cell, closed cell, and low permeability foams. Our foams meet MVSS302, UL94, and other industry standards and can be used in biomedical applications and industrial ventilation. - Industrial Foam for Neoprene Gaskets

Whether you manufacture pumps, piping, or marine products, our closed cell, flexible, and durable neoprene gaskets, which can be custom cut to any shape, provide optimal performance where movement can be anticipated. - Industrial Sound Abatement Solutions

Our solutions dampen high and low frequencies using the right materials and thicknesses, improving worker efficiency and comfort and assisting in OSHA compliance. Our substrates reflect heat and resist dirt or water, and our adhesives accommodate many temperature requirements or material types.