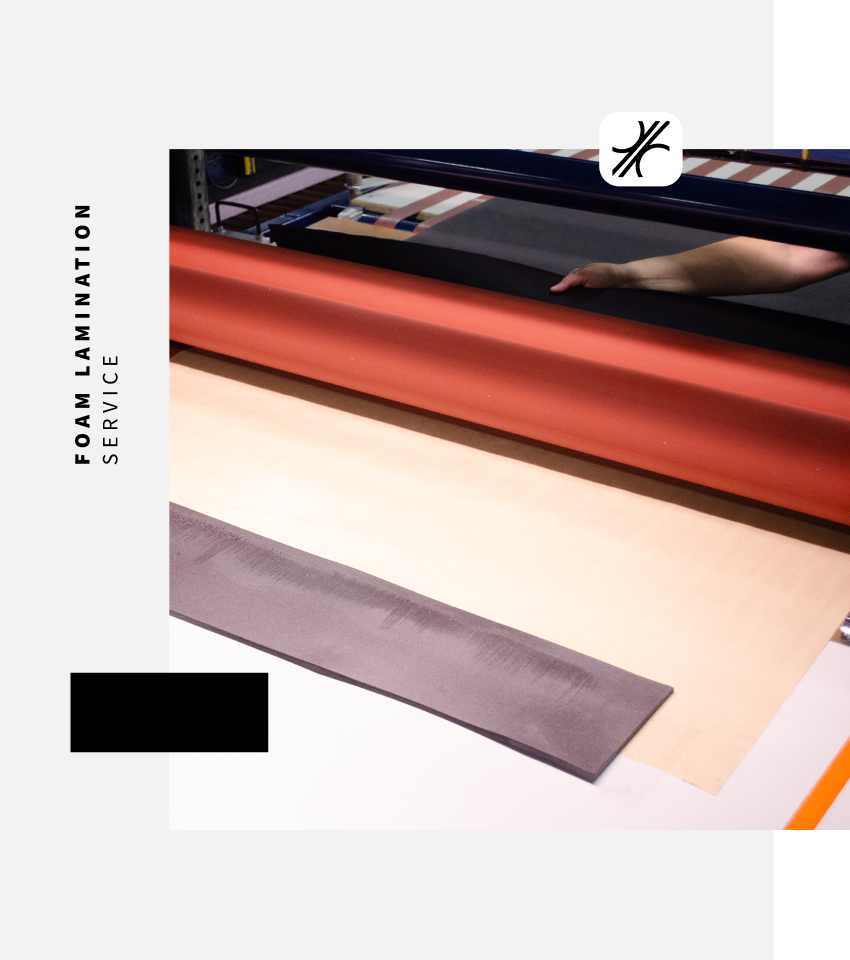

Foam Lamination Services

Precision-Bonded Foam for Multi-Layer Performance

Foam lamination allows materials to be combined into engineered structures that deliver improved durability, cushioning, insulation, and performance. At Amcon, lamination is used to create multi-layer assemblies, bonded packaging components, and high-strength foam systems that perform in demanding environments.

Whether you’re building custom inserts, vibration-control pads, medical components, or multi-material packaging systems, laminated foam provides the form, function, and consistency required for high-performance applications.

How Foam Lamination Works

Foam lamination bonds two or more materials into a single engineered sheet or shaped component. Amcon uses several advanced bonding methods tailored to material type, part geometry, and production volume:

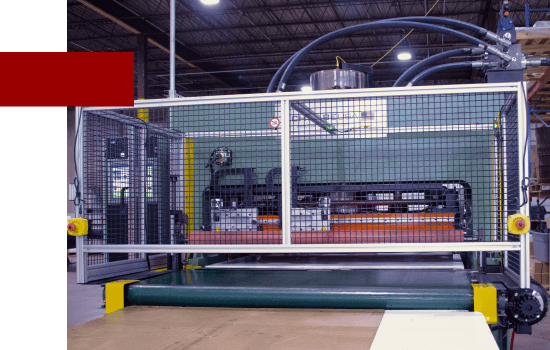

- SmartFoam™ Lamination Systems

- Our automated SmartFoam machines apply uniform adhesive coverage and controlled pressure to create strong, consistent bonds. This system reduces variation, eliminates excess adhesive, and improves repeatability across large production batches.

- Robotic Gluing

- For complex shapes or precision bond placement, our robotic gluing systems apply adhesive beads with pinpoint accuracy. This method is ideal for shaped components, multi-layer assemblies, and parts requiring controlled glue weight or exact placement.

- Heated Plank Lamination

- Heated plank lamination bonds foam sheets or blocks without adhesives, using controlled heat and pressure to form a seamless, durable bond. This technique is ideal for thicker materials, full-plank assemblies, and applications requiring a clean, chemical-free bond line.Once laminated, the foam materials function as a single engineered structure with predictable performance characteristics. This unified construction enhances durability, consistency, and functional control—setting the foundation for a wide range of performance advantages.

Benefits of Laminated Foam

Foam lamination enhances both structural and functional performance across a wide variety of applications. Key advantages include:

Combine different densities, thicknesses, or foam types to achieve hybrid performance—soft cushioning paired with firm structural support.

Bonded layers resist shearing, deformation, and delamination, even in demanding or high-use environments.

Compatible with polyethylene (PE), cross-linked polyethylene (XLPE), polyurethane (PU), EVA, vinyl nitrile (VN), and specialty materials.

Skived sheets and laminated planks allow precise control over thickness for engineered components and assemblies.

A single laminated part often replaces multiple separate components, improving manufacturing efficiency and reducing handling steps.

Dual-color laminations and clean bond lines can improve presentation, especially in custom packaging and case inserts.

Common Applications for Laminated Foam

- Protective Packaging & Case Inserts

Multi-layer assemblies designed for improved fit, cushioning, and presentation. - Vibration Control & Isolation Pads

Layering foams of different densities to manage shock, vibration, and load distribution.

- Medical Supports & Cushions

Multi-density foams engineered for comfort, stability, and structural accuracy.

- Industrial Gasketing & Sealing

Bonded layers for precise thickness control and consistent performance.

- OEM Components & Fabricated Parts

Laminated sheets or shapes used in equipment, assemblies, and custom fabrications. - Sports, Fitness & Outdoor Products

Multi-layer foam systems designed for impact absorption and long-term durability. - Manual hot air lamination

Using handheld hot air guns to manually laminate intricate, detailed, and short run products utilizing a no VOC bonding process that yields precise results and requires a high level of individual operator skill and dexterity. Used commonly for closed cell polyethylene foam assemblies. - Manual hot glue lamination

Using handheld hot glue guns to manually laminate intricate, detailed, and short run products utilizing a low VOC bonding process that yields precise results and requires a high level of individual operator skill and dexterity. Used commonly for both open cell polyurethane and closed cell polyethylene foam assemblies. - Manual water-based spray adhesive lamination

Using handheld spray glue guns to manually laminate intricate, detailed, and short run products utilizing a no VOC water based bonding process that yields precise results and requires a high level of individual operator skill and dexterity. Used commonly for open cell polyurethane foam assemblies.

PACKAGING

VIBRATION CONTROL

MEDICAL

INDUSTRIAL

OEM COMPONENTS

OUTDOOR

How Amcon Differentiates Its Lamination Capabilities

- SmartFoam™ Automation

- Ensures uniform adhesive distribution and consistent bond strength across large production runs.

- Robotic Adhesive Application

- Delivers precise glue placement for complex geometries and eliminates human variation.

- Heated Plank Capability

- Allows adhesive-free bonding, stronger structural joints, and seamless full-plank assemblies.

- Integrated Converting Workflow

- Lamination is tightly integrated with CNC routing, waterjet cutting, die cutting, skiving, and contour cutting for complete part production in-house.

- Material-Neutral Expertise

- We evaluate density, cell structure, thermal behavior, vibration response, and application environment to recommend the right lamination approach for each project.

- Prototype-to-Production Scalability

- Fast prototyping, predictable repeatability, and large-scale production capacity.

Partner with Amcon Foam for Foam Lamination

At Amcon Foam,

We deliver laminated foam components cut, shaped, bonded, and engineered exactly to your specifications.

“We’ve been sourcing Amcon foam products to use in thousands of our client facilities for more than two decades. Their product quality and customer service are second to none.”

KYLE F.

President, Company Confidential