Foam Skiving

Custom Foam Fabrication and Converting

Foam skiving is a precision foam converting technique used to slice foam blocks into thinner sheets with remarkably tight tolerance control. At Amcon Foam, we use skiving to create consistent, uniform foam layers that meet your exact specifications for thickness, density, and performance.

Whether you’re building multi-layer packaging inserts, custom foam parts for your products, or medical support cushions, foam skiving allows you to get precisely the thickness you need from the material that performs best in your application.

Foam Skiving Gives You Material Sheets with Tight Tolerances

The skiving process involves feeding a foam block through a long, ultra-sharp blade or rotating band knife mounted on a horizontal or vertical skiving machine. As the foam is passed through the blade, thin layers are peeled or sliced off to the desired thickness, often down to tolerances as tight as ±0.030″.

Foam Skiving Works on Many Types of Foam

- Polyethylene (PE)

- Cross-Linked Polyethylene (XLPE)

- Polyurethane (PU)

- EVA foam

- Vinyl Nitrile (VN)

- EPDM, EPE, EPP and other specialty foams

Foam skiving can be performed before or after other converting processes such as lamination, die cutting, waterjet cutting, or adhesive backing.

At Amcon, we specialize in two types of foam skiving:

Roll Skiving

Roll skiving involves feeding the foam material between two knurled rollers that compress the foam and push it through a rotating cutting blade. This process offers higher speed skiving that is consistent and suitable for most applications.

Roll skiving excels at producing consistent sheet thickness over large quantities, making it a cost-effective choice for applications like laminated foam assemblies, industrial gasketing, or large-format packaging liners.

Vacuum Skiving

Vacuum skiving is an advanced foam slicing process that uses vacuum suction to hold the foam block in place during cutting. This method allows for extremely precise control over sheet thickness while maintaining flatness and uniformity across the entire surface area.

By minimizing movement and deformation during cutting, vacuum skiving is ideal for producing thin foam sheets with tight thickness tolerances. It’s particularly useful when slicing soft or low-density foams that might otherwise compress or warp under traditional skiving methods.

Skiving for Foam Converting and Fabrication

Provides Many Benefits

Foam skiving gives you complete control over the thickness of your foam sheets. You’re not stuck with industry-standard thicknesses like 1/4″, 1/2″, or 1″. At Amcon, we can produce custom thicknesses on demand.

By slicing thicker blocks into thinner sheets, skiving maximizes yield from a single foam block. That translates to less waste, better cost control, and optimized material utilization, especially when working with high-performance or specialty foams.

Need to build foam assemblies with variable performance layers—like a soft cushioning core and a firm outer shell? Skived sheets are ideal for:

- Laminated constructions

- Multi-durometer applications

- Foam-and-film or foam-and-adhesive assemblies

Our team can skive, laminate, and cut to spec, and it’s all in-house.

Uneven foam thickness can lead to inconsistent sealing, uneven pressure distribution, and product damage during transit. Skiving eliminates those variables and ensures every part performs as expected.

Foam skiving supports both small batch prototyping and large-scale production runs. Whether you need 10 sheets for R&D or 10,000 inserts for full-scale packaging deployment, we deliver consistent results on time and within spec.

Skived Foam Can be Used to Fabricate Foam for Many Applications

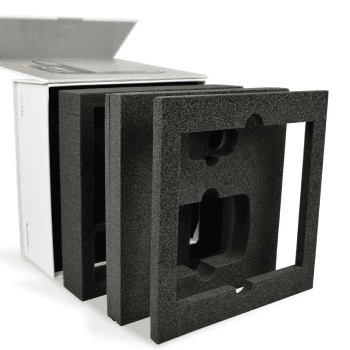

- Protective packaging inserts for electronics, medical devices, and fragile components

- Foam gasketing and sealing materials for HVAC, industrial enclosures, and automotive assemblies

- Custom medical pads and supports where cushioning and uniform contact are critical

- Vibration isolation pads in appliances, machinery, and transit cases

- Layered foam assemblies for branded packaging, cases, or multi-function materials

- Thermal and acoustic insulation panels requiring controlled thickness and performance

CASE INSERTS

INDUSTRIAL

MEDICAL

PACKAGING

CUSHIONING

INSULATION

Partner with Amcon Foam for Precise Foam Skiving

At Amcon Foam,

Skiving is just one part of our comprehensive foam converting capabilities. From material selection to final fabrication, we help OEMs and packaging designers bring their ideas to life with foam solutions that meet exact technical and performance requirements.

“We’ve been sourcing Amcon foam products to use in thousands of our client facilities for more than two decades. Their product quality and customer service are second to none.”

KYLE F.

President, Company Confidential