Foam Convoluting

Profiled Foam for Cushioning, Airflow, and Acoustic Performance

Foam convoluting is a converting method that shapes foam into a contoured, “egg-crate” profile to improve cushioning, airflow, and surface contact. By cutting repeating peaks and valleys into the foam, convoluting increases comfort, enhances pressure distribution, and can provide acoustic benefits in certain applications.

Convoluted foam is commonly used across industries for protective packaging, cushioning, acoustic treatment, and comfort applications. At Amcon, we fabricate foam components for these categories and can integrate convoluted surfaces based on application needs

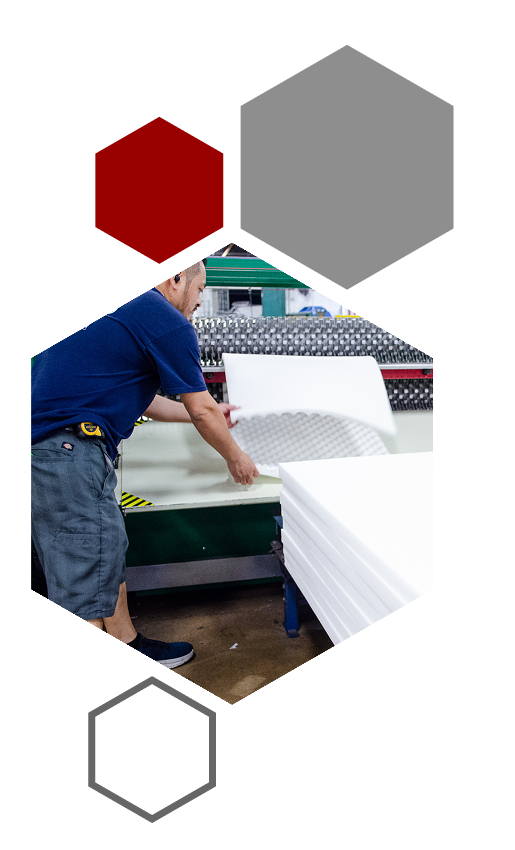

How Foam Convoluting Works

Foam convoluting is typically performed using a specialized cutting or profiling machine that brings two foam surfaces together against a contoured blade or roller. As the foam passes through the machine, matching peaks and valleys are cut into the material to form a repeatable pattern.

The process can be used on:

- Flat foam sheets

- Skived or laminated foam layers

- Specific thicknesses tuned to performance requirements

By adjusting pattern height, pitch, and profile shape, our team can tailor cushioning performance, airflow characteristics, and contact area to meet the needs of your product or packaging design.

Convoluting can be integrated with other converting processes—such as skiving, lamination, die cutting, waterjet cutting, or contour cutting—to produce finished components ready for assembly or final use.

Convoluted Foam Provides Many Benefits

Convoluted foam provides several advantages over flat foam surfaces, especially where comfort, airflow, or acoustic behavior matter.

Peaks and valleys allow the foam to compress more gradually, improving comfort, reducing pressure points, and providing better weight distribution.

The open channels created by the profile support airflow around the product or user, which can help with temperature regulation and moisture management.

Convoluting can reduce material usage compared to solid, flat profiles while still achieving the required cushioning and performance.

Profiled foam can help scatter and dampen sound waves, making convoluted foam a useful option in select sound control and acoustic treatment applications.

Pattern geometry can be tuned to support different levels of firmness, compression, and recovery, allowing the same base material to be adapted across multiple applications.

Common Applications for Convoluted Foam

Convoluted foam is used in a wide range of industries wherever comfort, fit, and energy absorption are important. Typical applications include:

- Top and bottom convoluted pads to cradle products and reduce impact during shipping and handling.

- Cushions, overlays, and positioning supports that improve comfort and manage pressure points.

- Profiled surfaces designed for improved airflow and body conformity.

- Foam profiles used in enclosures, rooms, and equipment housings to help diffuse and dampen sound.

- Lids and base pads that conform to irregular shapes while keeping equipment secure.

- Comfort padding, protective gear, or support surfaces that benefit from added airflow and contouring.

INSERTS

MEDICAL

MATTRESS TOPPERS

ACOUSTICS

EQUIPMENT CASES

PRODUCT PROTECTION

How Amcon Differentiates Its Foam Convoluting Capabilities

- Broad Material Compatibility

- We work with polyurethane (PU), polyethylene (PE), cross-linked PE (XLPE), and other specialty foams to match performance, durability, and comfort requirements.

- Integrated Converting Workflow

- Convoluting is fully integrated with our skiving, lamination, CNC routing, die cutting, waterjet cutting, and contour cutting capabilities, allowing us to produce complete parts, not just raw sheets.

- Custom Patterns and Performance Tuning

- Profile height, spacing, and geometry can be tailored to achieve specific cushioning, airflow, or acoustic behavior, based on your application.

- Prototype-to-Production Support

- We support everything from early prototyping and design trials to high-volume production runs, maintaining consistent quality and performance across batches.

- Application-Focused Engineering

- Our team evaluates load, environment, comfort, and acoustic needs to help you choose the right foam type, profile, and thickness for your design.

At Amcon Foam,

We combine specialized convoluting equipment with broad foam converting expertise to deliver precise, repeatable, and application-ready profiled foam.

Amcon delivers convoluted foam components cut, profiled, and engineered to your exact specifications—ready to perform in your most demanding applications.

“We’ve been sourcing Amcon foam products to use in thousands of our client facilities for more than two decades. Their product quality and customer service are second to none.”

KYLE F.

President, Company Confidential