Die Cutting

Custom Foam Fabrication and Converting

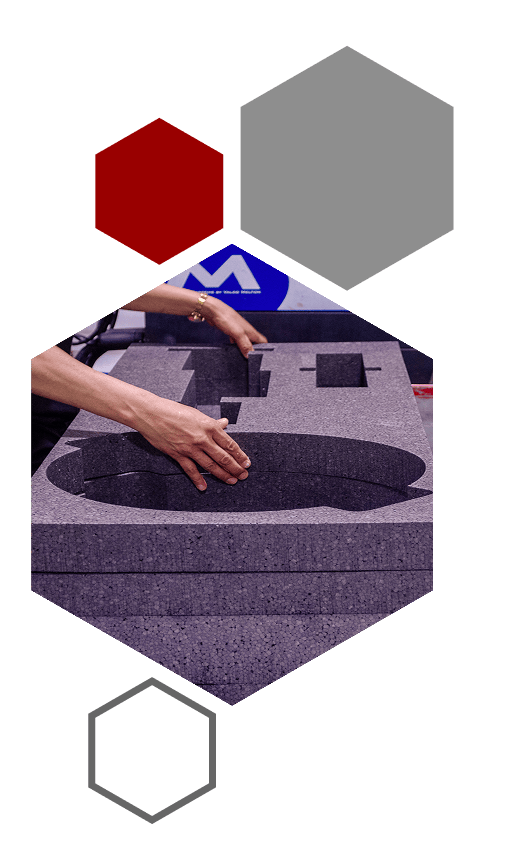

Foam die cutting is a manufacturing process that uses a custom-shaped steel rule die to cut foam materials into consistent shapes and sizes quickly, cleanly, and at scale. At Amcon Foam, we use die cutting to produce high volumes of precision foam parts with consistent dimensions, tight tolerances, and high repeatability.

From industrial gaskets and seals to custom packaging inserts and cushioning components, die cutting is a cost-effective, high-efficiency solution for flat foam parts.

Die Cutting is Scalable, Repeatable, and Precise

Die cutting begins with creating a custom steel rule die, which is a thin, sharp blade shaped to match your part’s profile and mounted into a die board. Foam sheets or rolls are then placed into a hydraulic or rotary press, which uses high pressure to stamp out the shapes. Die cutting is the preferred method for producing large quantities of uniform foam parts. While it takes a bit of time to create a custom die at the outset, once that die is created, the manufacturing process is fast and simple.

Depending on part geometry, production volume, and material, we offer both flatbed die cutting (for thicker materials and complex shapes) and rotary die cutting (for thin foams and high-speed production).

Die Cutting is Compatible with a Wide Range of Foams:

- Polyethylene (PE)

- Cross-linked polyethylene (XLPE)

- Polyurethane (PU)

- Expanded Polyethylene (EPE)

- Expanded Polypropylene (EPP)

Die Cut Foam

Provides Many Benefits

Once the die is created, foam parts can be cut rapidly and in bulk, making this an ideal method for:

- Production lines

- Kitting operations

- Contract packaging

- OEM component sourcing

Die cutting drastically reduces per-part cost as volume increases, making it one of the most economical options for repetitive designs.

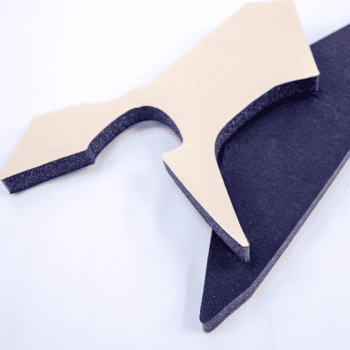

Modern die cutting equipment offers excellent dimensional accuracy, producing parts with:

- Consistent thickness

- Smooth, well-defined edges (you may note some concavity when die cutting thicker materials). Ask one of our sales professionals to guide you through our process.

- Minimal variation across batches

This helps create parts like gaskets, seals, and components that must fit tightly within housings or assemblies.

Die cutting works seamlessly with PSA-backed foams and laminated composites, allowing for quick application and assembly. We can apply adhesives, liners, and secondary layers before or after die cutting, depending on your production workflow.

Die cutting is highly efficient, especially when combined with optimized nesting software. Our team ensures you get maximum yield from each foam sheet, helping you reduce material costs and environmental impact.

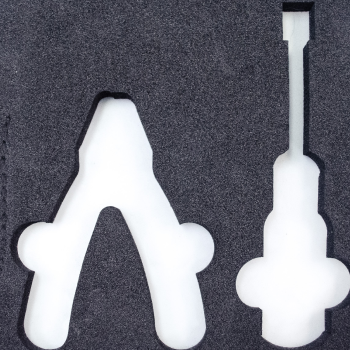

While not used for deep 3D contours, die cutting excels at producing:

- Flat gaskets

- Inserts with cutouts

- Layered stack-ups

- Simple cavities and shapes

For products that need to be flat-packed, mounted, or layered, this method delivers unmatched speed and consistency.

Common Applications for Die-Cut Foam

- Protective packaging inserts for tools, electronics, and medical equipment

- Gaskets and seals for HVAC, industrial, and automotive systems

- Foam pads and spacers for vibration isolation and cushioning

- Medical and orthopedic foam components

- Sound-dampening materials for electronics and enclosures

- Retail foam packaging with clean, branded presentation

- Laminated multi-layer assemblies in manufacturing and OEM products

CASE INSERTS

INDUSTRIAL

SPACERS

MEDICAL

CUSHIONING

PACKAGING

Partner with Amcon Foam for Die Cutting Foam Fabrication

At Amcon Foam,

We offer in-house die design, fabrication, and cutting capabilities, giving you a single-source partner for complete foam part production. We have several different types of die cutting machines at our converting facilities, allowing us to scale up to full production or create short-run kits for testing or specialty packaging.

We collaborate with engineers, designers, and buyers to ensure every part meets the exact demands of your application, from design to delivery.

“We’ve been sourcing Amcon foam products to use in thousands of our client facilities for more than two decades. Their product quality and customer service are second to none.”

KYLE F.

President, Company Confidential