Contour Cutting

Custom Foam Fabrication and Converting

Contour cutting is a foam converting method that allows for the creation of complex, three-dimensional shapes with smooth, precise edges. Using computer-controlled cutting systems, our team at Amcon Foam can transform foam blocks or sheets into custom parts with various curves, tapers, and intricate profiles, all to your precise specifications. Custom contour cut foam parts can be ideal for packaging, insulation, protective padding, and OEM components.

Unlike straight die-cutting or standard slicing, contour cutting gives you true shape freedom, giving parts the ability to conform to irregular surfaces or securely cradle delicate equipment.

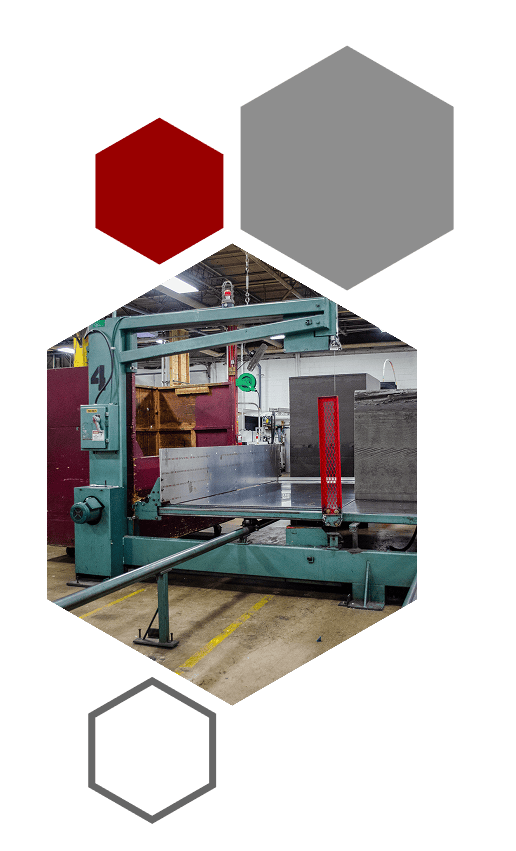

How Contour Cutting Works

Foam contour cutting is performed using high-speed band knife systems equipped with CNC (computer numerical control) guidance. The blade is tensioned and guided along a programmed path, allowing it to cut smooth, flowing curves and complex outlines through the foam.

Contour Cutting Works on Nearly Any Type of Foam:

- Polyethylene (PE)

- Cross-linked polyethylene (XLPE)

- Polyurethane (PU)

- Expanded Polyethylene (EPE)

- Expanded Polypropylene (EPP)

There are two primary types of contour cutting:

Horizontal Contour Cutting

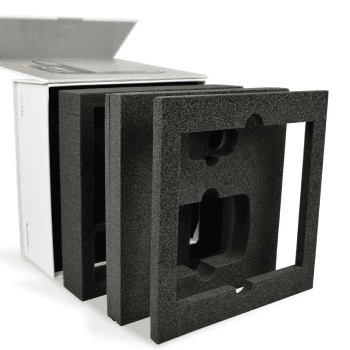

In horizontal contour cutting, the blade moves across the foam in a horizontal plane, cutting along the x- and y-axes. This method is best for producing:

- Foam pads or inserts with internal cutouts

- Profiled foam layers

- Parts with variable cross-sections across their width

It’s especially effective when cutting thin foam sheets or creating custom-shaped packaging cavities with consistent depth. This contour cutting method is ideal for flat, layered, or profile-based designs.

Vertical Contour Cutting

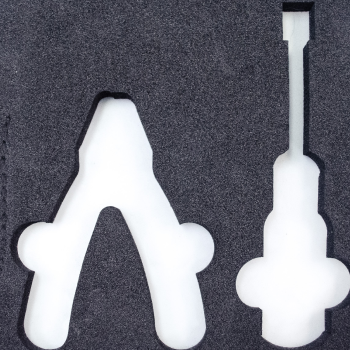

Vertical contour cutting involves a vertically mounted blade that slices down through the foam along the z-axis. This allows us to cut full-height foam pieces with curved, angular, or asymmetric exterior profiles that can be used for:

- Tool case inserts

- OEM foam components

- Branded or molded packaging with unique contours

Both methods are compatible with a variety of foam types, including polyurethane (PU), polyethylene (PE), cross-linked PE (XLPE), and more.

Contour Cutting for Foam Fabrication

Provides Many Benefits

Contour cutting allows for the creation of product-specific shapes that match your exact geometry. That means better protection, a cleaner presentation, and reduced material waste.

Using CAD-based control systems, our contour cutters deliver tight tolerances and repeatable results, even for intricate curves or layered foam assemblies. Every part is cut to spec with minimal variation.

Custom contour-cut foam means fewer adjustments, shims, or spacers during final packaging or assembly. The foam simply drops into place, saving time and improving consistency on the production line.

By closely following the shape of your product, contour-cut foam provides better distribution of impact forces, less movement during transit, and higher compression uniformity. This is especially important for delicate or irregular items.

Unlike traditional die cutting, contour cutting is digitally programmed with no tooling or physical dies required. That means:

- Faster turnaround

- Lower upfront costs

- Easy design changes

- Perfect for prototyping or custom runs

Common Applications for Contour-Cut Foam

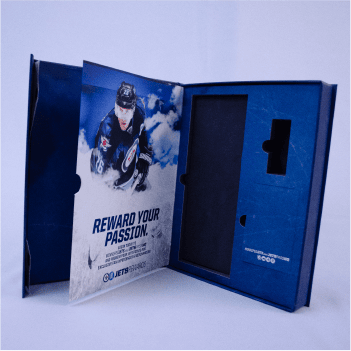

- Custom case inserts for tools, electronics, medical equipment, and optical devices

- Protective packaging for high-value or fragile components

- Automotive and aerospace foam parts with complex geometries

- Medical positioning and support pads

- Retail and product display packaging with branded contours

- Acoustic foam shapes for sound control applications

- Layered foam assemblies for energy absorption or insulation

INSERTS

VEHICLES

MEDICAL

PACKAGING

CUSHIONING

INSULATION

Partner with Amcon Foam for Contour Cutting and Foam Fabrication

At Amcon Foam,

We combine cutting-edge equipment with deep industry expertise to provide you with the highest-quality contour-cut foam components. Whether you need a small prototype batch or large-volume production.

Whether you're an OEM in need of tight-tolerance foam components or a packaging designer looking for custom-fitted inserts, contour cut foam from Amcon delivers the performance you need.

“We’ve been sourcing Amcon foam products to use in thousands of our client facilities for more than two decades. Their product quality and customer service are second to none.”

KYLE F.

President, Company Confidential