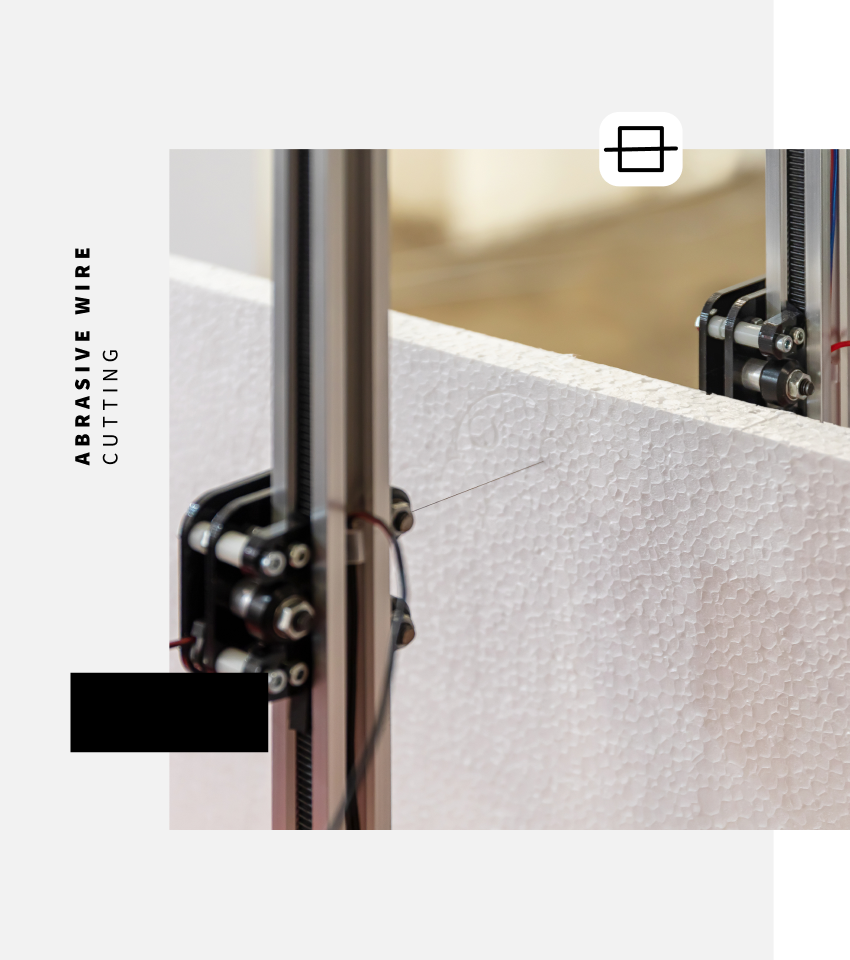

Abrasive Wire Cutting

Precision Cutting for Soft, Thick, and Specialty Foams

Abrasive wire cutting is a versatile foam converting method that uses a tensioned abrasive wire to produce clean cuts, smooth surfaces, and accurate profiles in a wide range of foam materials. This method is especially effective for cutting thick blocks, soft formulations, and specialty foams that do not respond well to traditional blades or high-heat cutting methods.

At Amcon, abrasive wire cutting expands our ability to fabricate high-quality components for packaging, cushioning, insulation, and OEM assemblies where accuracy, material integrity, and clean edges matter.

How Abrasive Wire Cutting Works

Abrasive wire cutting uses a continuous wire coated with fine abrasive particles. The wire moves at controlled speed and tension, cutting through the foam with minimal heat and low mechanical force.

Key steps in the process:

- Wire Movement: The abrasive wire travels along a programmed path, guided by machine controls or CNC systems depending on part complexity.

- Material Feed: Foam blocks or sheets are fed into the moving wire, allowing the abrasive surface to remove material cleanly and consistently.

- Low-Heat, Low-Distortion Cutting: Unlike hot-wire cutting, abrasive wire cutting does not melt foam. This prevents discoloration, deformation, or heat-affected edges.

- Profile and Straight Cuts: The method supports straight cuts, angled cuts, and smooth profile shaping depending on the required geometry.

This process is ideal when material integrity is a priority and when precise, uniform edges must be maintained across large or thick foam pieces.

Benefits of Abrasive Wire Cutting

Abrasive wire cutting provides several advantages for manufacturers and product designers working with foam components.

Produces high-quality surface finishes without the melting, smearing, or compression found in some traditional cutting methods.

Cuts cleanly through materials that are difficult to process with blades or routers, including soft polyurethane, thick PE blocks, and specialty foams.

Prevents heat-related issues such as warping, odor, or color change.

Enables consistent thickness, height, and profile accuracy for large-format or complex parts.

Compatible with a broad range of foams including PU, PE, XLPE, EVA, EPE, EPP, and custom formulations.

Efficient for straight or gently contoured cuts where precision and edge quality are more important than tight-radius detail.

Common Applications for Abrasive Wire-Cut Foam

Abrasive wire cutting is used across industries that require clean, uniform cuts in thicker or softer foam materials.

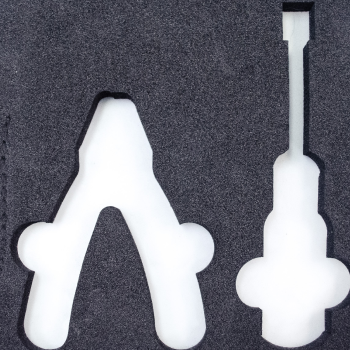

- Protective Packaging & Cushioning Pads

Large pads, layers, and blocks used to protect equipment and components during shipping and storage. - Medical & Comfort Components

Pads, supports, wedges, and ergonomically shaped foam parts for therapeutic and medical use. - Insulation & Thermal Barriers

Foam sheets and blocks used for temperature control and insulating assemblies. - OEM and Industrial Components

Foam parts used as spacers, supports, vibration-damping elements, and interface layers. - Recreational, Sports & Fitness Products

Larger cushion elements, mats, and comfort components made from soft or specialty foams. - Large-Format Foam Panels

Applications that require smooth, uniform panels without visible blade marks or heat-affected edges.

CUSHIONING

MEDICAL

INSULATION

INDUSTRIAL

SPORTS

PACKAGING

How Amcon Differentiates Its Abrasive Wire Cutting Capabilities

- Material-Neutral Expertise

- We work with a wide range of foam chemistries (PE, PU, XLPE, EPE, EVA, EPP, VN, and more) to match the right material and cut quality to your application.

- Integrated Converting Workflow

- Abrasive wire cutting is supported by CNC routing, waterjet cutting, die cutting, contour cutting, skiving, and lamination—allowing us to produce complete, application-ready parts.

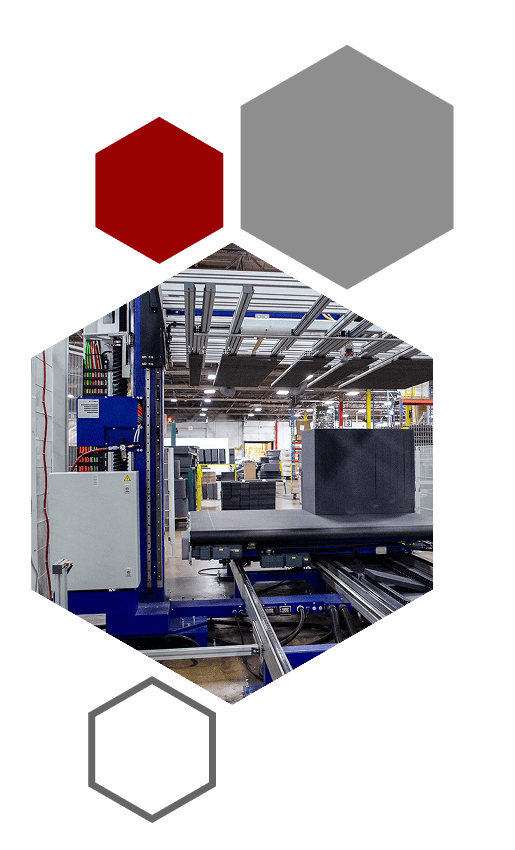

- Large-Format Capabilities

- Our equipment supports large blocks and sheets, enabling consistent cuts across oversized or high-thickness materials.

- Prototyping & Production Scalability

- From functional prototypes to full production runs, we help refine designs, optimize nesting, and ensure consistent quality.

- Prototype-to-Production Support

- From initial prototype through high-volume orders, our team supports design revisions, nesting optimization, and process selection so you get high-quality parts at an efficient per-part cost.

Partner with Amcon Foam for Abrasive Wire-Cut Foam

At Amcon Foam,

We deliver abrasive-wire-cut foam components that are cut, profiled, and engineered to your exact specifications—ready for integration into packaging, assemblies, or finished products.

“We’ve been sourcing Amcon foam products to use in thousands of our client facilities for more than two decades. Their product quality and customer service are second to none.”

KYLE F.

President, Company Confidential