Choosing the right packaging foam for products is one of the most important things shippers can do. It can help you reduce damage to products during freight, decrease your costs, increase the quality of your customer service, and severely reduce the headaches of dealing with returns, damaged products, reverse logistics, and more.

When it comes to packaging a product for transit, choosing the right foam can make the largest difference. But there are hundreds of types of foam, begging the question: what is the best type of foam to package my products with?

When choosing a packaging foam for your products, there are several important factors to take into account.

Consider the Sensitivity of Items

Packaging foam is meant to protect items while in transit, but certain types of foam can actually damage items, especially those that are sensitive to static or abrasive surfaces.

If you are shipping sensitive electronic devices that can be damaged by static electricity, it’s imperative to package them in the right type of ESD foam or anti-static foam. These types of foam help dissipate electro-static charges that can be generated through friction, which is common as items shift around while in transit. If you are looking for an ESD foam for packaging, make sure it meets the EIA-541 Packaging Material Standards for ESD Sensitive Items.

Some foam can also be slightly abrasive, which can damage sensitive items when they are shipped. If you have a concern about fragile paint or surfaces on your items that need a soft, non-abrasive foam (e.g. crosslinked polyethylene or expanded polyethylene foam), let your foam provider know. There are many types of foam that boast non-abrasive properties for sensitive items. Look for foams with a class “A” rating.

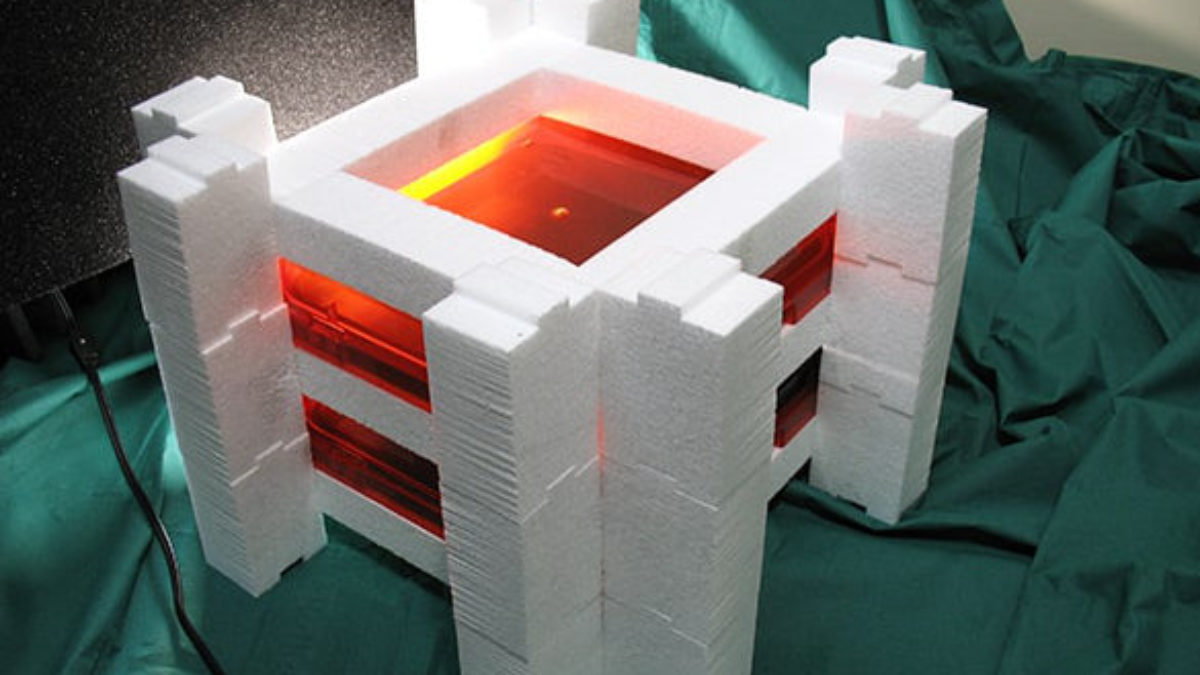

Is Climate Control an Issue?

If you are shipping temperature sensitive items or items that need to be kept within a certain temperature range, it’s necessary to use a foam, like expanded polystyrene, expanded polyethylene foam, and expanded polypropylene, which act as suitable insulators. If you are shipping pharmaceuticals or perishable products that rely on temperature control, the right foam can help carriers keep those products in their required climate while in transit.

Customization is Possible

From custom crates and pallets to all manners of foam shapes, sizes, cutouts, and layers, it’s entirely possible to customize the shipping and packaging materials for any type of product. When you work with the right foam fabricator, this process is easy. Simply let them know what types of industry regulations or standards you need to meet (i.e. ISTA or ASTM packaging test standards), what types of products you are shipping, and what your budget is for your packaging solution. Everything from corrugated materials to all sorts of protective packaging and dunnage can be used to create the right packaging for your products, no matter what you need to ship.