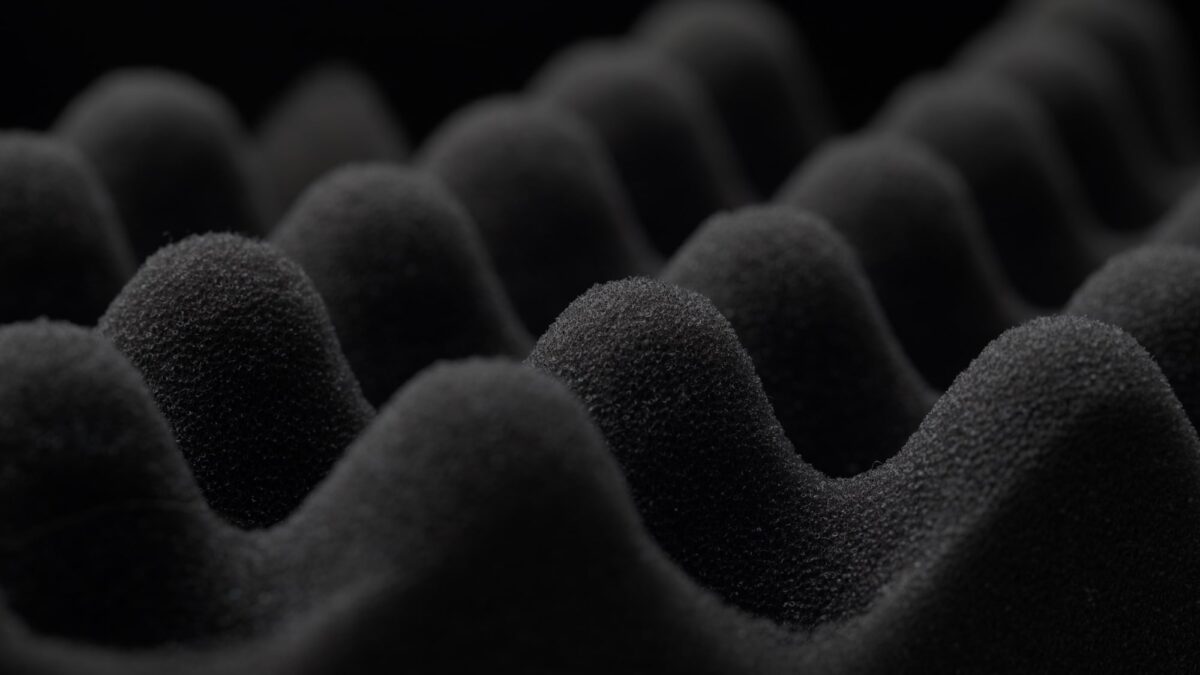

When it comes to foam and thermoplastics, it’s all about the cell structure. Even the smallest changes to a foam’s cells can drastically alter its capabilities, completely transforming it into a material that is either incompatible with your application or the perfect fit.

What are Many Foams Made of?

At base level, many foams are made from cells that are frozen after a heated polymer has been solidified. The foam can change based on the materials that have been used. These can include:

- Ethylene

- Vinyl acetate

- Polyethylene

- Acrylonitrile

- Butadiene

- Polypropylene

- Polystyrene

- Polyurethane

- Polyvinyl chloride

- Many others

These synthetic cellular materials have complex microstructures that change the foam’s innate properties. The foam cells themselves form an interconnected network, and based on whether those cells are left open or closed, the foams will have very different characteristics.

Open Cell vs Closed Cell Foam

The cells within a foam can either be open or closed, which greatly impacts the permeability of a piece of foam. Open cell foams are generally highly permeable—they will allow gas and water to pass through them. This is because the cells are open and the cell walls are interconnected (known as a reticular structure). These types of foams are also generally softer than closed cell foams. This makes them ideal for filtration applications.

Closed cell foams have a cellular structure with closed walls, preventing the flow of gas and water. This is why closed cell foams are more commonly used in gasketing and sealing applications.

Find more detailed information on the difference between open and closed cell foams, as well as examples of each type of foam.

Rigid Foams vs. Non-Rigid Foams

If the walls of the cells within a foam material are inflexible and do not give way when pressure is applied, the foam is considered a rigid foam. If the foam cell walls move when under stress, conforming to whatever is applying stress to them, the foam is considered flexible. Keep in mind that both open and closed cells foams can be considered flexible; the same applies for rigid foams.

Foam Additives

Some additives can be combined with certain types of foams to give them new properties. Some varieties of polyurethane, for example, can be treated with additives during the polymerization process to allow the foam to actively resist bacterial growth. The additive becomes a permanent part of the cellular structure of the foam. Other additives can be used to make foams antistatic (ESD foam) or conductive, among many other properties.

We stock countless varieties and classifications of foam, allowing you to choose a foam that provides the protection and properties your application needs. Get in touch with Amcon today for all your foam needs.