Waterjet Cutting

Custom Foam Fabrication and Converting

Waterjet cutting is a high-precision, cold-cutting custom foam fabrication method that uses a high-pressure stream of water to slice through foam materials cleanly and accurately. There’s no heat, distortion, or mechanical stress on the material. Just clean cuts.

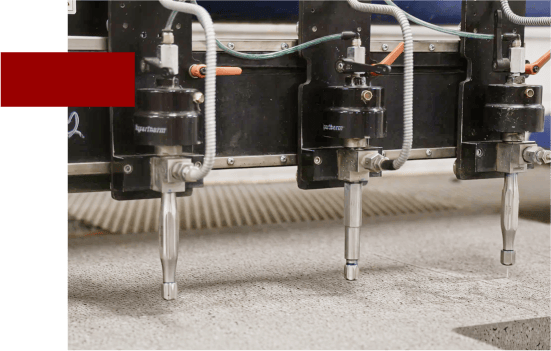

At Amcon Foam, we use advanced waterjet systems to cut everything from dense closed-cell foam to soft, flexible polyurethane, giving our clients a fast, accurate, and highly repeatable fabrication method for complex parts and custom packaging inserts.

Precision and Flexibility for Clean Foam Fabrication

Waterjet cutting systems work by forcing pressurized water (up to 60,000 psi) through a narrow, computer-controlled nozzle to make precise cuts through nearly any type of foam. This process is used In custom foam converting because it’s non-abrasive and clean. It’s usually used to avoid overcutting, material degradation, and jagged edges.

Using CAD-based designs, our team can cut foam sheets or blocks into custom shapes, contours, cavities, and inserts with exceptional accuracy and clean edges. There’s minimal material waste and no tooling required. This foam fabrication process is perfect for low- to mid-volume production, product launches, or custom foam solutions with frequent design updates.

Waterjet Cutting Works on Nearly Any Type of Foam

- Polyethylene (PE)

- Cross-linked polyethylene (XLPE)

- Polyurethane (PU)

- Expanded Polyethylene (EPE)

- Expanded Polypropylene (EPP)

Waterjet Cutting for Foam Fabrication

Provides Many Benefits

Waterjet cutting allows for extremely tight tolerances, making it ideal for intricate components, protective packaging, and complex geometries. Even fine details, curves, and tight corners are executed cleanly and consistently.

Unlike laser or die-cutting, waterjet cutting is a cold-cutting process. This means there’s no melting or warping, no hard edges or heat-affected zones, and no chemical degradation of foam structure. It can be used on thermally sensitive foams.

With waterjet cutting, there are no costly dies or molds. Digital designs are created, allowing for faster prototyping and revisions, shorter lead times, lower costs for short-run or custom projects, and easy iteration for product design changes.

Waterjet cutting is a nesting-friendly process. Our team uses software to optimize material layouts, ensuring that you get the most parts per sheet and reduce foam waste. This lowers your total cost of production.

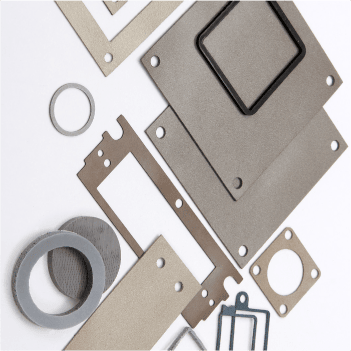

Waterjet-cut foam parts have smooth edges, tight tolerances, and no burn marks or fraying You get clean-cut foam with a finish that is smooth, straight, and specified to your product or packaging application.

Waterjet-Cut Foam is Used by Leading OEMs and as Custom Packaging

- Protective packaging inserts for electronics, medical devices, and more

- Custom case interiors for tools, military gear, and more

- OEM foam components for appliances, industrial machinery, automotive, and more

- Medical-grade cushioning and supports

- High-performance gaskets, seals, and spacers

PACKAGING

CASE INSERTS

VEHICLES

MEDICAL

INDUSTRIAL

CUSHIONING

Partner with Amcon Foam for Waterjet Cutting and Foam Fabrication

At Amcon Foam, we bring decades of experience in precision foam fabrication for parts and packaging in the most demanding industries. Our in-house waterjet capabilities allow us to turn your concept into reality fast, affordably, and with zero compromise on quality.

Our Foam Converting Facility Has

- 5 water jet machines (5 times more than local competitors)

- A 5-axis waterjet cutting machine (the only one of its kind in our area)

- 20+ cutting heads in our Minnesota and Colorado facilities

Whether you're an OEM in need of tight-tolerance foam components or a packaging designer looking for custom-fitted inserts, waterjet-cut foam from Amcon delivers the performance you need.

“We’ve been sourcing Amcon foam products to use in thousands of our client facilities for more than two decades. Their product quality and customer service are second to none.”

KYLE F.

President, Company Confidential