When it comes to custom foam fabrication, choosing the right cutting technique allows fabricators to achieve the precision, efficiency, and customization your foam needs for your specific application. At Amcon, our engineers and product designers work across industries—from packaging to automotive—to produce the best possible outcome for our clients. From tight tolerances to optimal per parts costs, we can help you customize your large-run orders in the best way possible.

What are some of the cutting fabrication techniques we use?

Our Custom Foam Cutting Techniques

Die Cutting

Die cutting is a highly versatile technique, ideal for producing large volumes of identical foam parts quickly and efficiently. It involves the use of a customized cutting die, which is pressed into foam sheets to cut specific shapes. This method is particularly effective for applications that require precision and consistency in shape and size.

Die cutting is commonly used to fabricate foam inserts for protective packaging, gaskets, and seals in industries such as automotive, electronics, and aerospace. For example, custom foam packaging inserts for delicate electronics are often produced using die cutting to ensure that each piece fits precisely and offers maximum protection.

Waterjet Cutting

Waterjet cutting is a highly precise, non-thermal process that uses a high-pressure stream of water to cut through foam. It offers exceptional flexibility in terms of the shapes and sizes it can produce, making it ideal for complex designs and applications where intricate detailing is required. Additionally, because it doesn’t involve heat, waterjet cutting preserves the integrity of the foam material, avoiding warping or distortion.

Waterjet cutting is commonly used to create custom foam parts for medical devices, automotive components, and industrial equipment. It is particularly effective for projects requiring intricate foam parts with smooth edges and complex geometries, such as custom foam gaskets and seals.

CNC (Computer Numerical Control) Routing

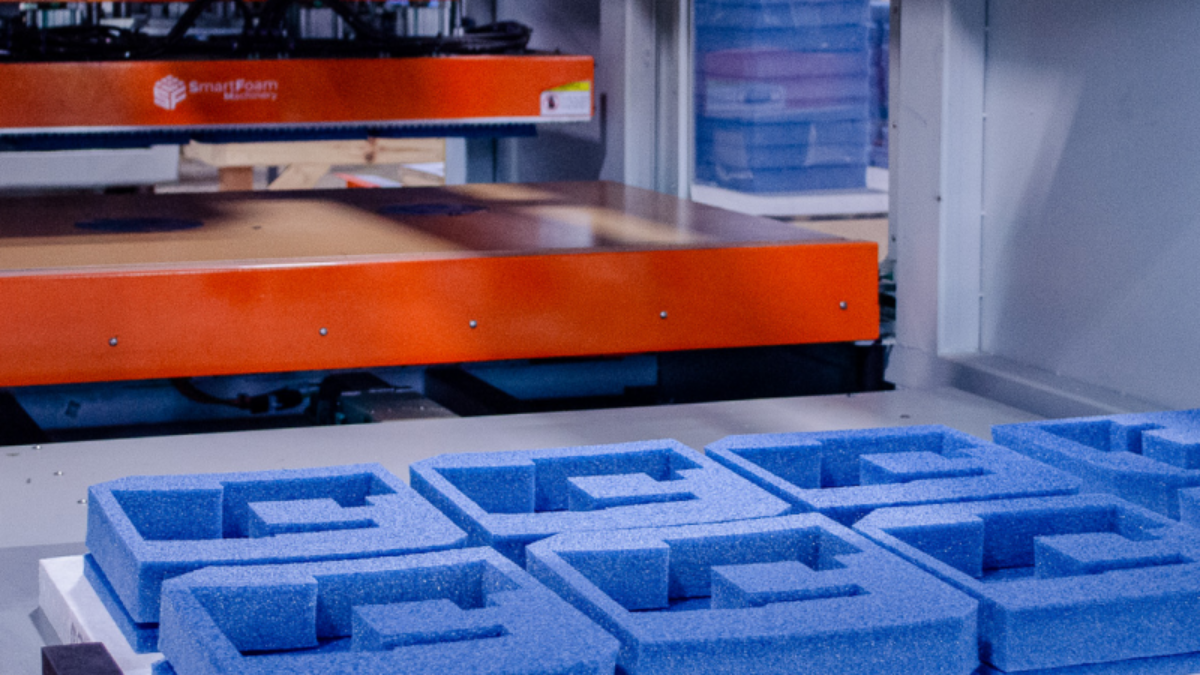

CNC routing is a computer-controlled fabrication process that uses precision tools to cut foam materials into highly detailed and intricate shapes. This method is ideal for producing prototypes, small production runs, and custom foam parts that require tight tolerances and complex designs. CNC routing offers significant flexibility in terms of shape, depth, and complexity, making it suitable for a wide range of applications.

CNC routing is often used to create foam components custom foam inserts for high-end packaging.

Thermoforming

Thermoforming is a process that involves heating foam sheets until they become pliable, and then molding them into a specific shape using a custom mold. This technique is particularly useful for creating durable, high-strength foam parts with a uniform surface finish. Thermoforming allows for the creation of complex three-dimensional shapes and is ideal for producing foam products with a smooth, finished appearance.

Thermoformed foam parts are often used in the automotive industry for vehicle interiors, such as dashboard padding and seat cushioning. Thermoforming can also be used to create custom foam packaging solutions for high-value products like medical equipment or consumer electronics.

Laser Cutting

Laser cutting uses a focused laser beam to cut through foam with precision and accuracy. This technique is best suited for applications requiring intricate designs, fine details, and smooth edges. Laser cutting offers minimal material waste and can cut through a variety of foam types with ease, making it ideal for creating complex foam parts.

Laser cutting is commonly used in the electronics industry for creating foam inserts, gaskets, and seals for sensitive components. It is also used to produce high-end custom packaging solutions for luxury goods, where the precision and clean edges offered by laser cutting are essential for creating a premium look.

How to Choose the Right Fabrication Technique for Your Application

Choosing the right foam cutting technique depends on several factors, including the complexity of the design, the volume of production, the type of foam material, and the application’s specific requirements. Here are some tips for selecting the best foam fabrication method:

- For High-Volume, Repetitive Cuts: die cutting is the best choice for high-volume production where consistent, precise shapes are required.

- For Intricate Designs and Complex Shapes: waterjet cutting and CNC routing are ideal for applications that demand fine details, custom geometries, or smooth edges.

- For Three-Dimensional Shapes and Smooth Finishes: thermoforming is perfect for creating complex 3D foam parts with a finished surface, particularly for automotive and packaging applications.

- For Small-Scale, High-Precision Projects: laser cutting is best suited for smaller production runs that require extreme precision and clean edges.

Find the Right Fabrication Technique for Your Foam

Each foam cutting technique offers its own advantages depending on the application and material requirements. Whether you need high-precision parts for medical devices or durable foam inserts for protective packaging, selecting the right cutting method ensures the highest quality and performance for your foam products. At Amcon, we can help you customize your foam to meet the specifications of your application. Get in touch with our team today for a consultation!