Beaded foams are highly versatile materials used in a wide range of applications and industries. These foams are valued for their light weight, durability, and customization potential. What exactly are beaded foams, and are they right for your application?

What Are Beaded Foams?

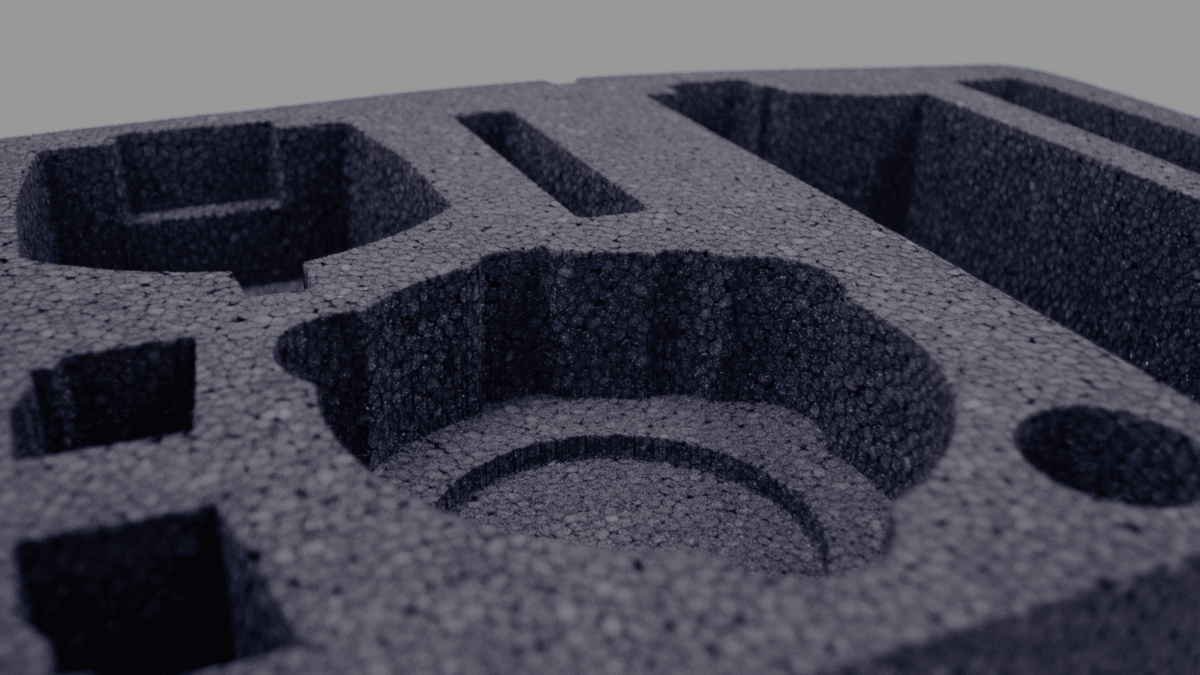

Beaded foams are materials made from small, expandable polymer beads that are heated and fused together to form solid foam structures. The most common types of beaded foams are Expanded Polystyrene (EPS), Expanded Polypropylene (EPP), and Expanded Polyethylene (EPE). The physical and chemical composition of each type of foam varies depending on the polymer used, which in turn affects the foam’s properties such as density, flexibility, and resistance to impact.

The manufacturing process of beaded foams typically involves the following steps:

- Pre-expansion: polymer beads are expanded using heat or steam, causing them to inflate as air or gas fills the internal structure.

- Aging: after expansion, the beads are allowed to cool and stabilize. This ensures uniformity in bead size and structure.

- Molding: the beads are then placed in a mold and heated again to fuse them together into a solid foam piece. The beads retain their cellular structure, giving the foam its characteristic appearance and properties.

Because of the cellular structure of beaded foams, they are lightweight yet durable, making them ideal for various industrial applications.

The Major Types of Beaded Foams

There are several types of beaded foams available, each with distinct advantages and disadvantages:

Expanded Polystyrene (EPS)

- Pros: EPS is lightweight, cost-effective, and has excellent insulation properties. It’s widely used in packaging, construction, and for insulating products.

- Cons: while durable, EPS is more rigid and brittle compared to other beaded foams, which limits its flexibility and impact resistance. It is also not as environmentally friendly due to its petroleum-based composition.

Expanded Polypropylene (EPP)

- Pros: EPP is highly resilient, flexible, and has excellent impact resistance, making it ideal for applications where cushioning and durability are key. It is also chemically resistant and recyclable.

- Cons: EPP is more expensive than EPS due to its superior performance characteristics. It also has lower thermal insulation properties compared to EPS.

Expanded Polyethylene (EPE)

- Pros: EPE foam is lightweight, flexible, and resistant to water, chemicals, and oils. It provides good cushioning and shock absorption, making it ideal for packaging delicate products.

- Cons: EPE has a lower density than EPP, which can reduce its durability in certain high-impact applications. It also provides lower thermal insulation.

Common Applications of Beaded Foams

Beaded foams are used across a wide variety of industries due to their versatility and unique physical properties. Some of the most common applications include:

Protective Packaging

Beaded foams, especially EPS and EPE, are frequently used in packaging fragile or sensitive products. Their ability to absorb shock and prevent damage during shipping makes them a go-to solution for companies that need cost-effective yet reliable packaging materials.

Automotive Components

EPP foams are widely used in the automotive industry for impact protection, sound insulation, and energy absorption in bumpers, door panels, and seating. Their resilience and durability make them a great choice for reducing vehicle weight while maintaining safety standards.

Point of Purchase Displays

Beaded foams are often used in custom point-of-purchase (POP) displays due to their lightweight nature and ease of customization. EPS foam, for example, can be cut and shaped into intricate designs that attract customer attention while supporting products effectively.

Insulation

EPS foam is frequently used in construction for thermal insulation. Its excellent insulating properties make it an ideal material for walls, roofs, and foundations in both residential and commercial buildings.

Sports and Safety Equipment

Beaded foams like EPP are also used in sports and safety equipment such as helmets, padding, and protective gear. The impact resistance of these foams helps reduce the risk of injury during high-impact activities.

How Beaded Foams Can Be Customized and Custom Fabricated

One of the greatest advantages of beaded foams is their versatility in customization and fabrication. Custom foam fabricators can manipulate beaded foams in various ways to meet the specific needs of their clients. Here’s how beaded foams can be customized:

Die-Cutting and Shaping

Beaded foams can be cut, shaped, and formed to fit any design requirement. Whether it’s creating complex shapes for packaging or custom inserts for point-of-purchase displays, foam fabricators can tailor the foam to match exact specifications.

Laminating

Beaded foams can be laminated with other materials to add durability, aesthetic appeal, or additional functionality. For example, a foam packaging insert can be laminated with a soft fabric layer to provide additional protection for sensitive products.

Color Customization

While beaded foams are typically available in standard colors like white (EPS) or black (EPP), they can also be custom colored during the manufacturing process to align with branding or product presentation requirements.

Density and Thickness Adjustments

The density and thickness of beaded foams can be customized depending on the specific application. For example, high-density EPP foam can be used for automotive parts, while lower-density EPE foam can be utilized for protective packaging.

Combination with Pressure-Sensitive Adhesives (PSA)

For certain applications, beaded foams can be fabricated with pressure-sensitive adhesive (PSA) layers, making them easier to install or apply in various products, from automotive components to building materials.

Interested in Beaded Foams for Your Application? Get in Touch with us Today for a Free Quote or Sample.