Cushioning curve is one of the most important metrics to consider in foam selection, particularly for packaging and cushioning applications. What is cushioning curve? How is it measured? Why is it important to your application?

These are the basics of cushioning curves and how they impact certain foam applications.

What is the Cushioning Curve of a Piece of Foam?

The cushioning curve effectively measures how well a piece of foam reacts under certain impact conditions. The measurement is based on the thickness of the piece of foam as well as how it performs throughout testing. This measurement is important not only because it gives you an indication as to whether a piece of foam will provide adequate protection, it’s also an important cost-saving factor in applications like foam packaging. Overspending on protective foam that is not necessary to keep products safe in transit leads to higher packaging and shipping costs.

It’s essential to find a piece of foam with the optimal cushioning curve for your products.

How is a Cushioning Curve Measured?

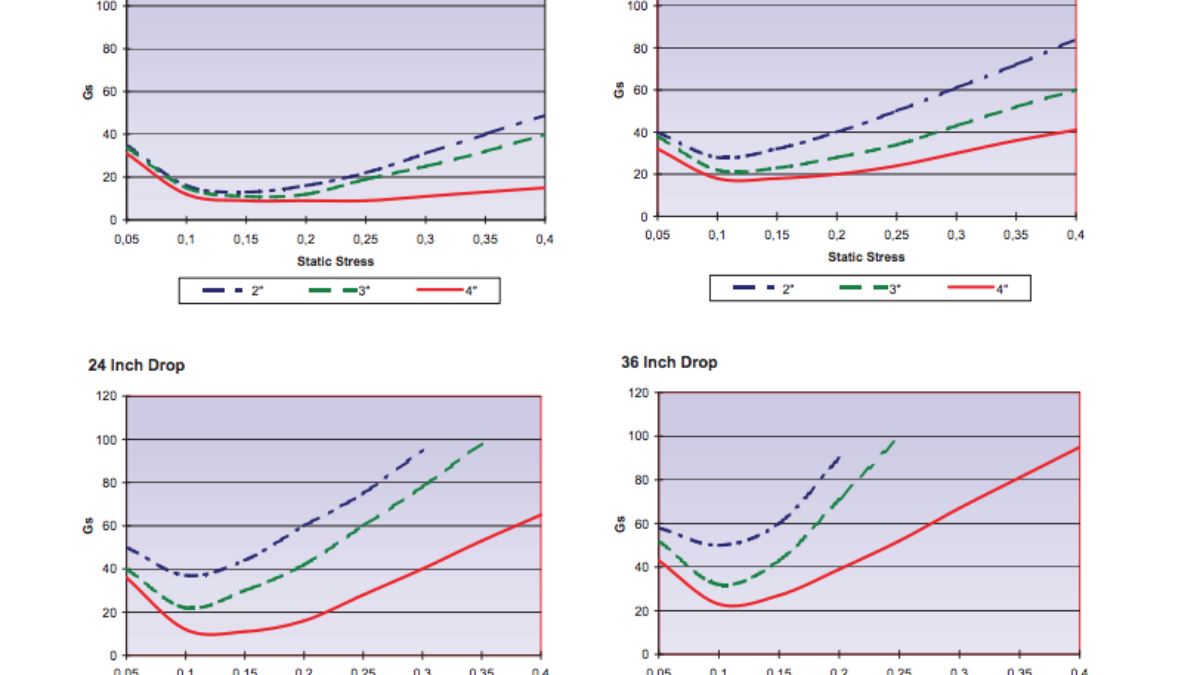

Cushioning curves are measured through a testing process that involves dropping a series of weights onto the foam from various heights, allowing testers to measure the reaction of the foam as the shock occurs. The static stress incurred is measured as well as how many inches the foam is compressed when the weight hits. Drop heights can generally include 12 inches, 18 inches, 24 inches, and 36 inches.

The actual cushioning curve is measured and graphed out, representing the compression of the foam at the moment of impact, at its most compressed state (as the full force of the weight and its drop are felt), and as the piece of foam recovers to its original state.

This measurement helps you determine if a piece of foam will fully absorb the predicted shock it could incur during transit. It’s critically important to know how the end user product will be shipping.

What to Do Once You Know the Foam’s Cushioning Curve

Once you have an exact measurement as to the cushioning curve of the foam you are working with, you can then determine the thickness and amount of foam you will need to adequately protect your items.

Consider the cushioning curve of the piece of foam you are using. How many inches can it compress (it’s cushioning curve), before stress is applied to the product. Next consider the potential damage that could happen to the package while it’s in transit. Using the force you can expect the package to incur, you now know how much of a particular type of foam to use for packaging and protective purposes.

Need help choosing a type of foam, its thickness, and the amount you need for your packaging? Get in touch with the foam fabrication experts at Amcon today.