Static-sensitive electronic devices, components, and parts need a special type of ESD foam for shipping and storage. These types of foams help protect from static electricity, which can damage electrical components as the items shift around while in transit. When choosing a foam for these types of items, it’s best to ensure that they meet EIA-541 Packaging Material Standards for ESD Sensitive Items. When it comes to choosing between anti-static and conductive foams, it helps to understand the differences between the two.

What is Anti-Static Foam?

Anti-static (ESD) foams are foams that help dissipate electro-static charges, which can easily damage sensitive electronic devices and parts. These types of foam are made from a static dissipative polyurethane and polyethylene material and have a surface resistance that measures between 109 – 1012 ohms.

It’s easy to identify most anti-static foams because of their pink coloring. ESD foams are chemically treated with anti-static agents that allow them to not generate static charges. However, they will allow static charges to pass through them. They prevent static from being built up by the friction of the item rubbing up against them while in motion. If you are using this type of foam in shipping and want to fully protect static-sensitive devices, make sure the item is placed in something that will shield it from outside electrostatic charges (like a silver conductive bag).

Keep in mind that anti-static foam generally is not reusable.

Static Dissipative Foam

You also have the option of choosing static dissipative foam. Dissipative foam is a type of foam that allows for static charges to flow to the ground more slowly than conductive materials. By controlling the speed in which charges go to the ground, the foam protects the material encased inside of it. This type of foam is generally either carbon-impregnated and colored black or surface treated and colored pink. Static dissipative foam has a low (or no) initial charge and prevents discharges to or from human contact. These types of foam have a 105 to 109 ohms per square.

What is Conductive Foam?

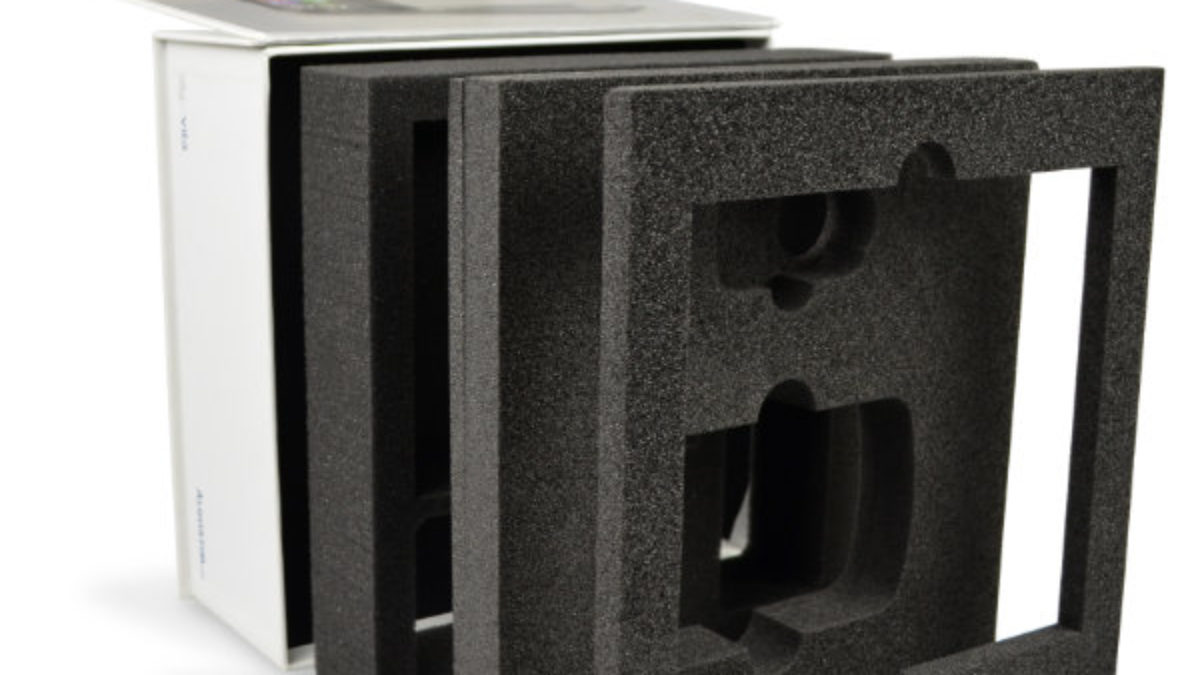

Conductive foam is a type of polyethylene foam that is filled with carbon, which is what gives it its conductive properties. It is generally identifiable by its black coloring and has a surface resistance of less than 10^6 ohms. Conductive foam protects electronic devices and components by acting as a Faraday cage, which blocks electromagnetic fields from reaching whatever it is surrounding. When using this type of foam, it is not necessary to place the item in something that will shield it from outside electrostatic charges. However, conductive foam is known to drain batteries if their conductive ends come in contact with the foam. If you are using this type of foam to ship or store electronic devices, be sure to shield batteries from the foam using a layer of insulation or another type of static dissipative foam.

Need to protect a static-sensitive electronic device? We can help. Get in touch with Amcon today to learn more about our foam options.