Shipping and storing delicate items requires foam that can adequately protect the item from impact and various environmental conditions during shipment. For items that are sensitive to surface scratches, you’ll also want to choose a protective packaging foam that is not abrasive. Some items may require foam like expanded polystyrene, but beaded foams are also a great option for many applications. These types of foam are great choices for packaging and can even be used as protective case inserts.

What are beaded foams, and why should you use them? There are many advantages to choosing this type of foam.

What are Beaded Foams?

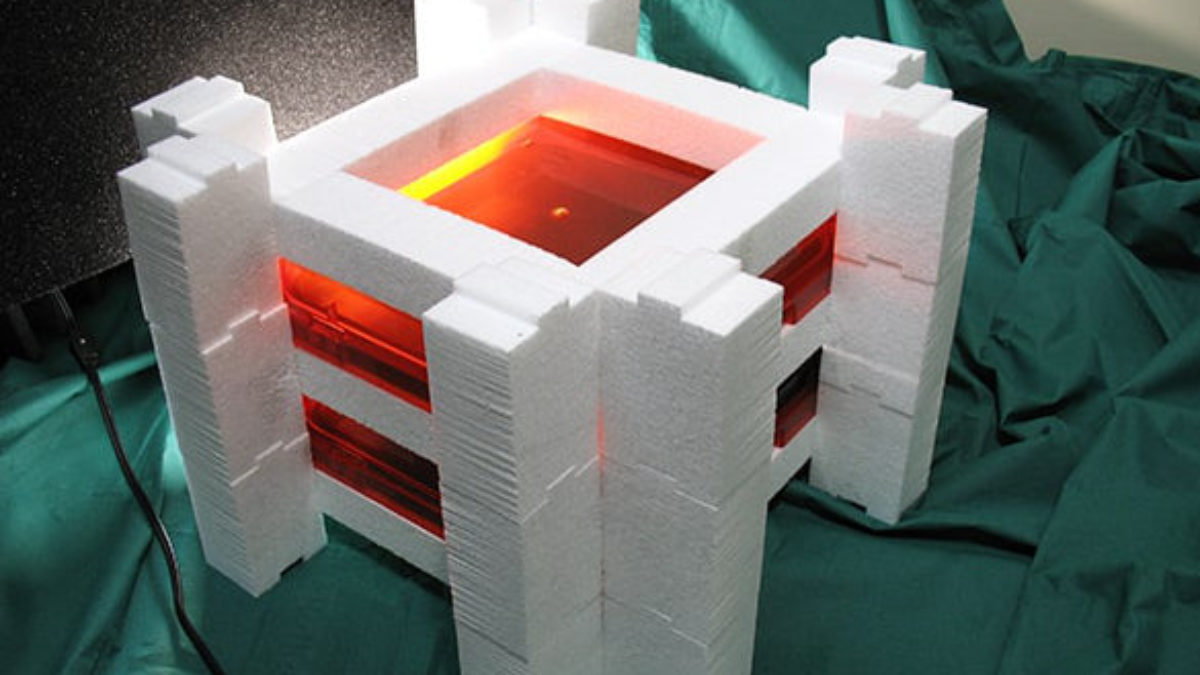

Beaded foams like expanded polystyrene (EP) , expanded polyethylene (EPE), expanded polypropylene (EPP), and beaded polyethylene (BPE) are special types of foam that are constructed by small beads that are interconnected. Beaded foams are manufactured by heating foam beads, which then expand to many times their size. After expansion, the beads are molded into varying shapes that be further cut to the desired size and fabricated into nearly any custom shape.

Beaded foams can be very cost-effective because they take much less energy to manufacture and fabricate , they possess very high strength to weight ratio (meaning you can protect more with less), and they can be a viable option for many applications.

The Benefits of Using Beaded Foams

Beaded foams are known for having a few beneficial properties. They:

- Lightweight

- Cost-effective

- Have high structural integrity and compression strength (high strength-to-weight ratio)

- Do not absorb easily moisture

- Have a high chemical resistance

- Are not abrasive (ideal for Class A surfaces)

- No off-gassing

- Can be recyclable

Many beaded foams are also aesthetically pleasing, which makes them ideal for case inserts for fragile devices, particularly if they are being used for sales and demo purposes. Beaded foams offer a low-cost, reliable way to protect large and small items that are sensitive to abrasive materials, vibration, and other environmental conditions.

Need help selecting a foam for your application? We can help. Get in touch with us today to find the right foam for the job.