Shipping large and bulky items requires careful attention to the packaging used to protect them. To ensure these items arrive at their destination unscathed, it’s important to choose a foam type that is specifically designed to absorb their weight, protect against shock, and deal with everything else that happens while items are in transit. With all the foam options you have available, how can you choose a foam that is ideal for your budget and the items you ship?

Factors to Consider When Selecting Foam for Shipping Large Items

Larger items tend to be heavy. Despite their size, they can also be fragile. When choosing a piece of foam for shipping protection, make sure it has the right properties and capabilities you need. These can include:

1. Shock Absorption

Shock absorption in foam refers to the ability of the material to absorb and dissipate energy generated by an impact or sudden force. When an object experiences an external force, the kinetic energy from the impact is transferred to the foam. The foam’s shock absorption properties determine how effectively it can absorb, distribute, and reduce the transmitted energy, thereby minimizing the impact and protecting the object or surface it cushions.

2. Density

Higher density foams often exhibit better shock absorption capabilities. The denser the foam, the more resistant it is to compression, making it effective at absorbing and dissipating impact energy. Choose a foam with an appropriate density that can protect your products. Higher density foams also offer better support and durability, which can be crucial for protecting heavy or delicate items.

3. Compression Strength

Compressive strength in foam refers to the ability of the material to withstand and bear a load or force applied perpendicular to its surface without significant deformation or damage. It is a measure of the foam’s resistance to compression, indicating how much pressure or force the material can handle before undergoing structural changes.

The ability of the foam to compress and then rebound to its original shape is crucial for effective shock absorption. The type of cell structure (open-cell or closed-cell) can influence compressive strength. Closed-cell foams, with their more rigid structure, often exhibit higher compressive strength.

4. Customization

Foam customization is essential to achieving 360-degree protection. It can also help you reduce your budget. When foam pieces are customized for your items and right sized for the packaging you use, material waste is reduced. This means you can be spending less money on wasted foam. When you multiply this by thousands of pieces, the savings add up. Foam fabrication runs with high yields can be an incredibly cost-effective way to create packaging, and it’s the best way to reduce damage to your items while in transit.

Which Types of Foam are the Best?

This entirely depends on the items you are shipping and the additional protection you need (ESD, thermal, etc.), but there are some types of foam that are more ideal for shipping large and bulky items, including:

- Polyethylene Foam: known for its excellent shock absorption and durability, polyethylene foam is versatile and can be customized to fit various packaging needs.

- Polyurethane Foam: with high-density options available, polyurethane foam provides robust protection against impacts and is suitable for heavier items.

- EPE Foam (Expanded Polyethylene): lightweight and flexible, EPE foam is ideal for large and irregularly shaped items. It offers good cushioning while remaining cost-effective.

- EPP Foam (Expanded Polypropylene): lightweight and possess excellent compressive properties, EPP is ideal for heavy items where compression set, and compression creep are a big concern.

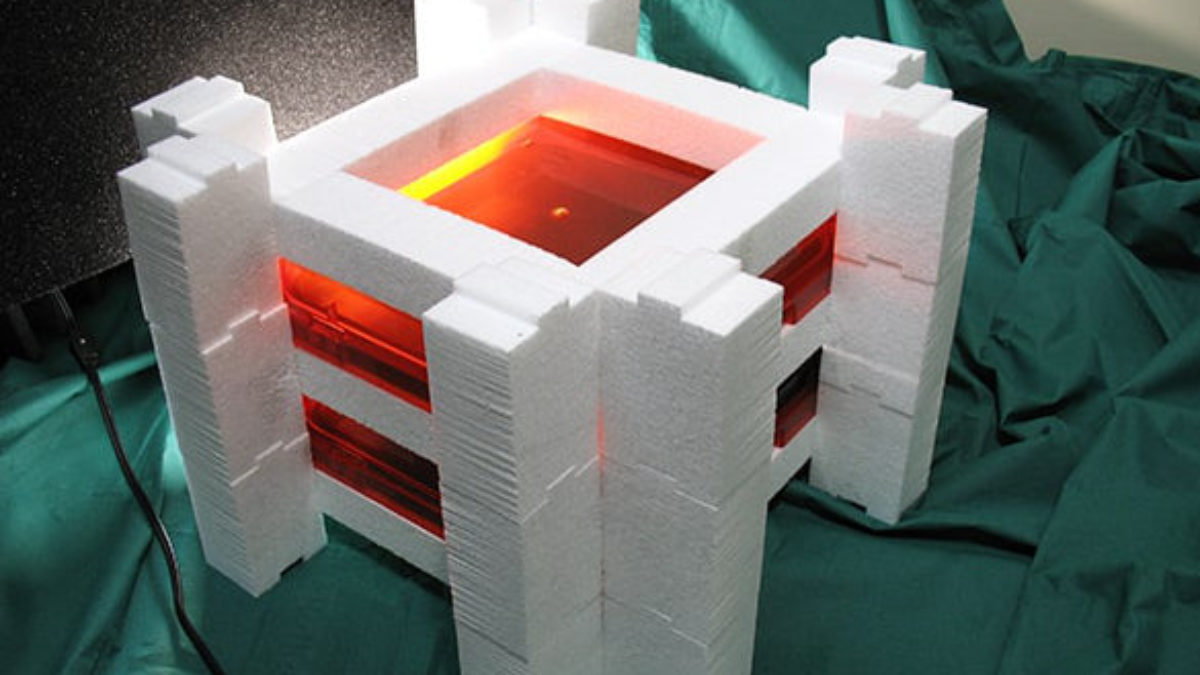

- EPS Foam (Expanded Polystyrene): EPS foam is lightweight, cost-effective, and provides insulation. It is commonly used for shipping fragile items.

- Crosslinked Polyethylene Foam: known for its enhanced durability and chemical resistance, crosslinked polyethylene foam is suitable for challenging shipping environments.

Choosing the right foam can make all the difference, but it’s also important to choose the right foam fabricator. At Amcon, we work with our clients to not only help them find the best foams for their application, but we also custom manufacture those pieces to perfectly fit their items and shipping containers. You will not get better performance and protection from your foam anywhere else.

Looking to protect large and bulky items while in transit? Get in touch with our foam experts today to find your ideal solution.