Electronic devices not only carry significant financial value but are also delicate, making them difficult to ship cost effectively and safely. Proper packaging is essential to protect these items from damage during shipping and foam packaging offers an optimal solution. These materials provide the best protection to ensure devices arrive at their destination in pristine condition, and they do so affordably. What types of protection do electronic devices need, and what are the advantages of using foam for shipping?

Find the most suitable types of foam and key considerations you should make when selecting them.

What Can Damage Electronic Devices During Shipping?

Electronic devices are susceptible to a range of potential damages during transit, including:

- Physical Damage: drops, impact shocks, and vibrations can cause internal and external damage to sensitive devices.

- Electrostatic Discharge (ESD): Sensitive components can be damaged by static electricity.

- Moisture: Humidity or liquid can lead to corrosion or short-circuiting.

Pressure Changes: Especially relevant for air shipping, where altitude changes can affect sealed components. - Abrasion: Many delicate electronics have surfaces that can be easily scratched by abrasive materials.

Why Foam is an Ideal Safeguard for Shipping Electronics

Many different types of foam create affordable and secure packaging solutions for electronics, providing ample:

- Shock Absorption: Many foams dissipate energy from impacts, reducing the risk of damage.

- Static Protection: Certain foams are designed to prevent electrostatic discharge, safeguarding sensitive electronic components.

- Moisture Resistance: Some foam types are resistant to moisture, providing an additional layer of protection.

- Abrasion Resistance: Certain foams such as Expanded Polyethylene (EPE) foam as well as Polystyrene Foam provide a class A surface which means products are protected from abrasion even when direct contact between the foam and the product occurs.

- Superior Customization: Foam can be cut and shaped to fit any device, ensuring stability and minimizing movement during transit.

The Ideal Foam Types for Shipping Electronic Devices

Several types of foam are well-suited for packaging electronics, each offering unique benefits. These types of foam include:

- Polyethylene (PE) Foam: Known for its shock absorption and vibration damping properties, PE foam is durable and strong, making it ideal for heavy or high-impact electronics like computers, monitors, televisions, etc.

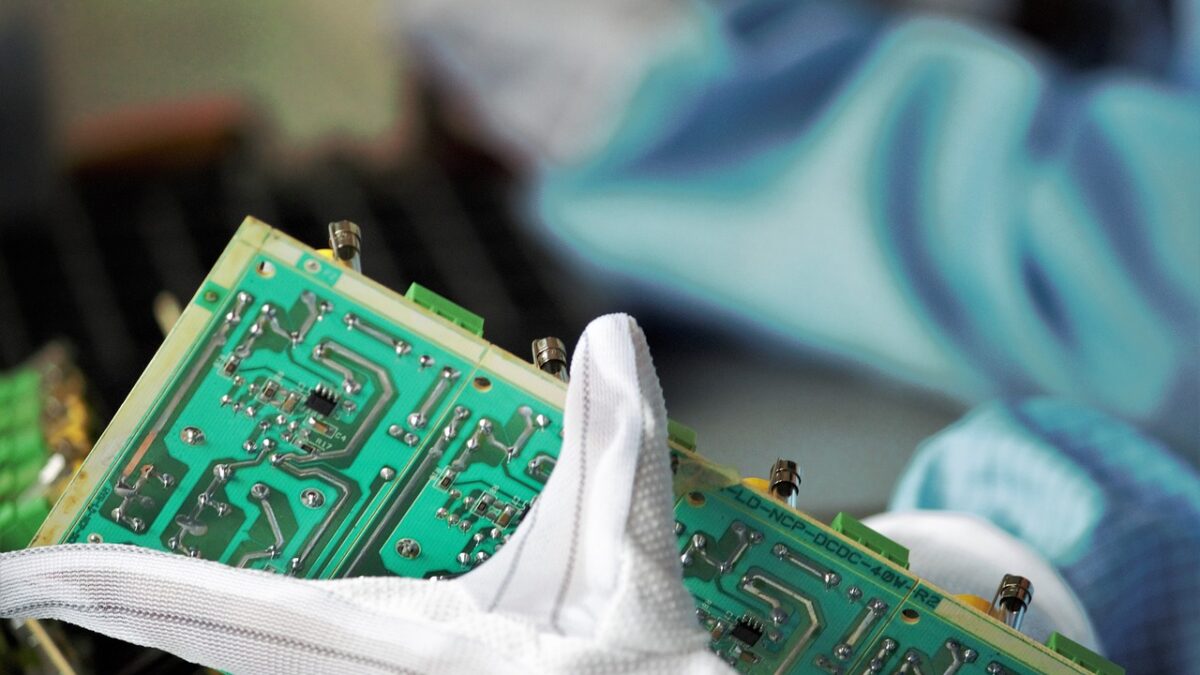

- Polyurethane (PU) Foam: PU foam is lightweight and available in various densities, allowing for customization to fit specific packaging needs. Its open-cell structure is excellent for delicate electronics that need gentle cushioning (like circuits boards, chips, etc.).

- Anti-Static Foam: Specifically designed to prevent electrostatic discharge, anti-static foam is essential for shipping electronic components sensitive to static electricity. It typically comes in both PE and PU variants, providing both physical protection and static safety.

- Polystyrene and/or Expanded Polyethylene (EPE): These are lightweight and non-abrasive foams that are commonly used to protect consumer electronics.

- Zotefoams: this family of foams offers high impact absorption, non-abrasive surfaces, resistance to many chemical, and static dissipative properties. The foams are also non-offgassing, which helps prevent contamination of sensitive components.

What to Consider When Choosing Foam for Shipping Electronics

Selecting the right foam involves several considerations to ensure maximum protection. What should you consider?

- Device Sensitivity: The choice of foam should correspond to the device’s vulnerability to shock, static, or moisture. Sensitive components may require anti-static foam, while heavier items might need the sturdiness of PE foam.

- Shipping Conditions: Consider the typical shipping environments and potential hazards. For long-distance or international shipping, more durable and moisture-resistant foam may be necessary.

- Environmental Factors: For businesses prioritizing sustainability, selecting recyclable or eco-friendly foam options can align packaging practices with environmental goals.

- Cost-Efficiency: While protection is the priority, it’s also important to consider the cost implications of different foam types. Balancing protection needs with budget constraints is crucial for cost-effective shipping solutions.

Find the Right Packaging Foam with Amcon Foam

Foam packaging stands out as a versatile and effective solution for the safe transport of electronic devices. By understanding the specific needs of each device and the unique properties of different foam types, businesses can ensure their products are protected from the myriad risks associated with shipping. With careful selection and customization, foam packaging can provide peace of mind for businesses and their customers, safeguarding valuable electronics from the warehouse to the end-user’s hands.

Need a Packaging Foam for Your Electronic Devices? Contact the Foam Experts at Amcon Today!