Traveling sales and demo cases are an integral part of the sales process for many industries. That’s why it’s so important for businesses to protect their products when on the road, in the air, and anywhere else. Sales and demo cases not only protect products while in transit, they also make products stand out during a presentation, which can help boost sales. Because of this, it’s essential to build the right case for your product, down to the type of foam you use as a case insert.

Here’s what you need to know about designing the right type of case.

Choose the Ideal Foam Based on Your Product

There are hundreds of types of foams on the market, each with their own characteristics that make them suitable for a vast array of products. Choosing the right foam type not only protects your products and makes them more presentable, it also effects the overall cost of the case you end up purchasing.

Some factors you should take into consideration when choosing a foam include:

- Abrasion: does your product scratch easily?

- Electro-static discharges: does your product need ESD protection?

- Thermal insulation: does your product need protection against temperature changes?

- Bulk: is your product small and delicate or larger and bulky?

- Usage: how often will your product be removed from the case for handling and presentation?

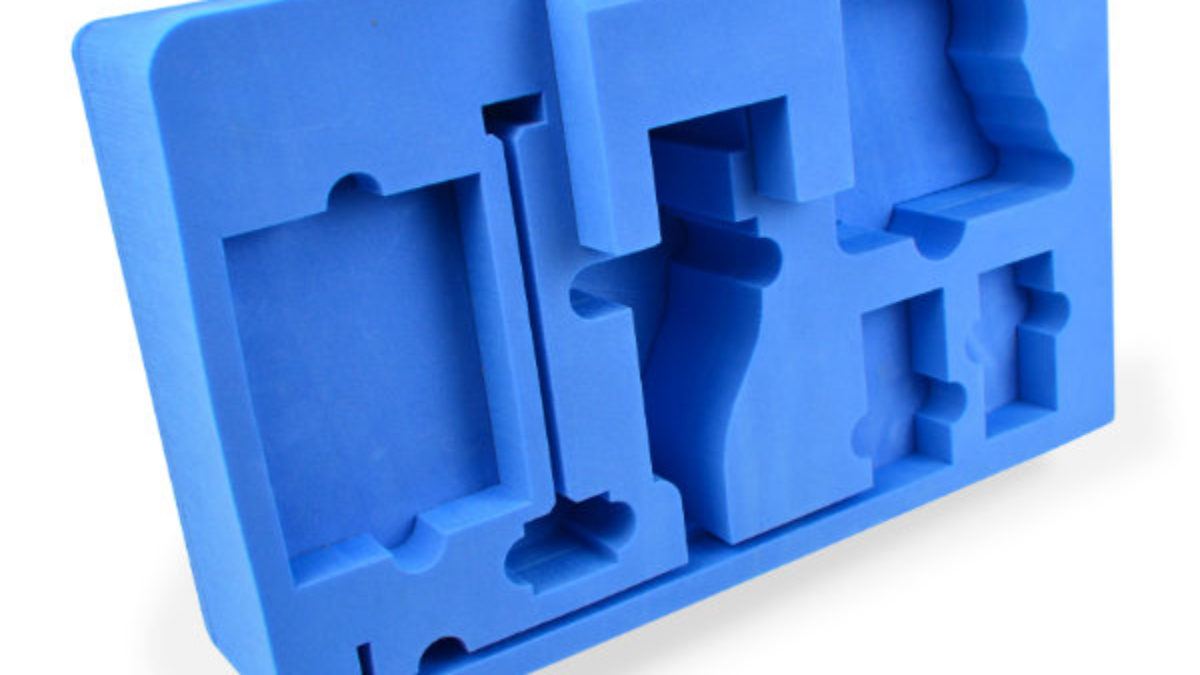

There are two areas in the case that will need foam: the base and the lid. Keep in mind that the same type of foam will not always be used for the base and the lid. Some foam types available to you are:

- Polyethylene Foam: a highly resilient, closed cell material that is used for its resistance to mold, mildew, bacteria as well as shock absorption and tear resistance

- Polyurethane Foam: a lightweight and soft open cell material that is used for its high shock absorption, flame resistance (meets UL 94 safety standards) and customization capabilities (it can easily be cut into various shapes, etc.)

- Cross-linked Polyethylene Foams (XLPE): these visually appealing, closed-call foams are durable and offer class A surface protection.

- Beaded Polyethylene Foam: light weight, durable, easy to fabricate, and laminates well. It is a class A surface.

We’ll help you select the right foam material for your case interior to prevent damage to your product, extend its useful life, and allow it to hold up to repeated use no matter how many times you remove or reinsert it.

For more information on case insert and foam, see the following pages based on the types of products being used:

The Best Choice For Your Product

Between airport baggage kiosks, bumpy rides in rental cars, and repeated openings and closings, sales and demo cases need to withstand a lot of use that borders on abuse. Let us help you choose the ideal foam for your case. Get in touch with Amcon today.